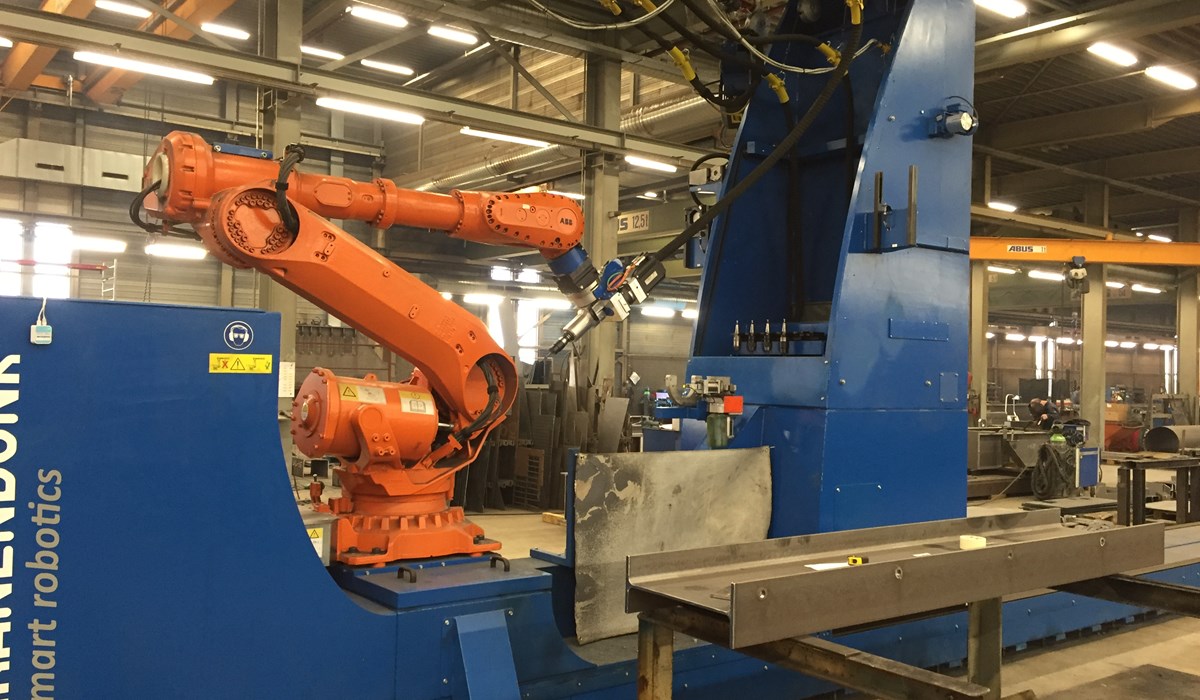

The Multi-Process Robot on Track offers unmatched flexibility for the processing of steel parts. The robot uses up to 5 different tools to drill, tap, cut, weld and mark on any steel part. The track is a fully coordinated robot axis, giving the system a large working area.

Flexibility for the processing of steel parts

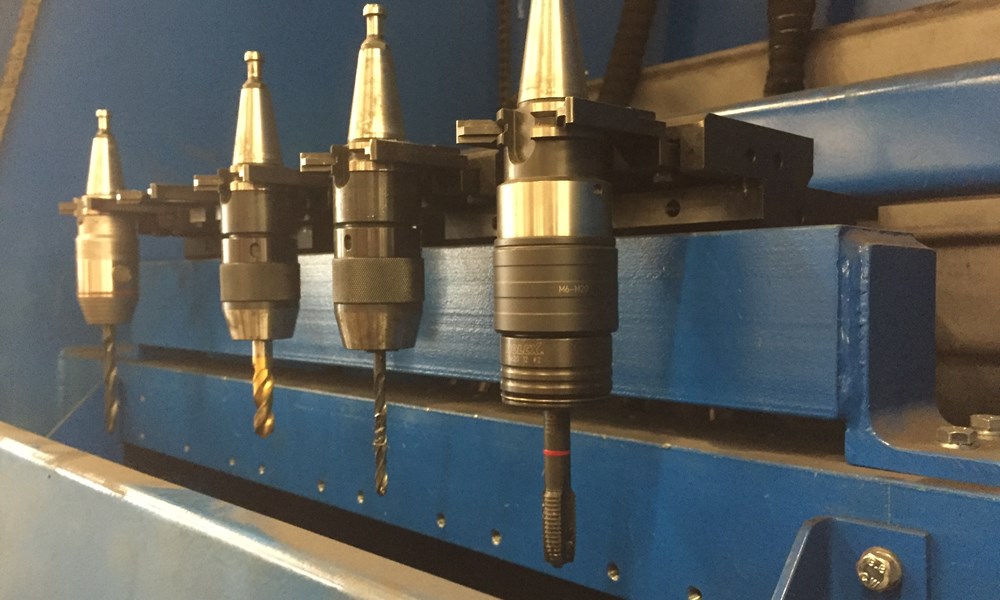

Up to 5 different tools to drill, tap, cut, weld and mark on any steel part

Large working area

Flexibility for the processing of steel parts

Up to 5 different tools to drill, tap, cut, weld and mark on any steel part

Large working area

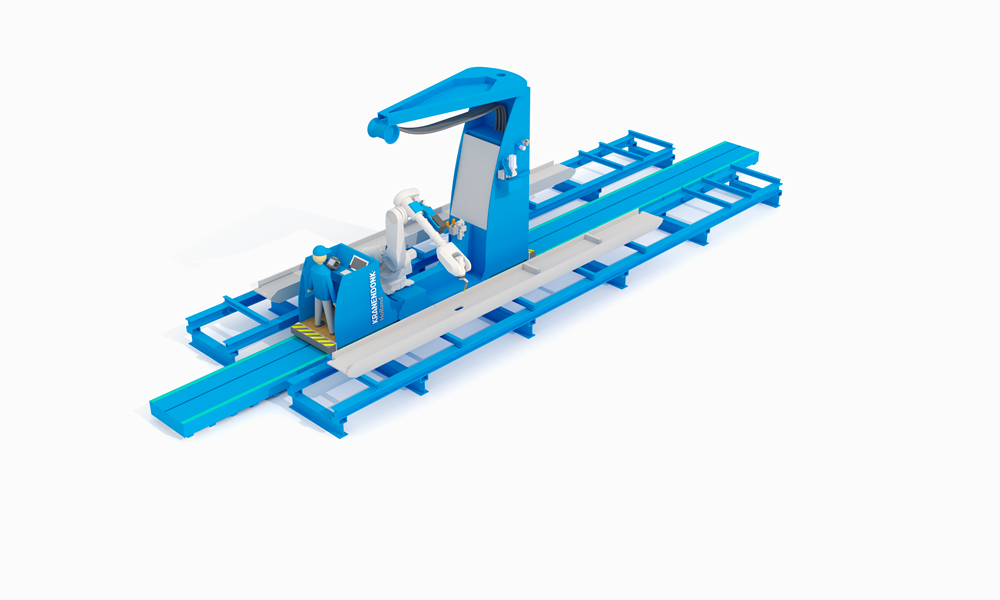

The Multi-Process Robot on Track offers unmatched flexibility for processing steel parts. The large industrial robot on a high-precision track features 5 different tools, enabling you to drill, tap, cut, weld and mark on any steel part. The track is a coordinated robot axis, giving a large effective working area of >100m2.

The Multi-Process Robot on Track offers unmatched flexibility for processing steel parts. The large industrial robot on a high-precision track features 5 different tools, enabling you to drill, tap, cut, weld and mark on any steel part. The track is a coordinated robot axis, giving a large effective working area of >100m2.

Controlling the robot is made easy, with smart software and large touchscreen. One operator can reach high productivity with robotic quality and precision. Smart safety features enable welders and fitters to work closely to the robot. Meaning that your workers can use the robot in a cooperative way. The way of the future, workers and robotics on an open shop floor, made possible by smart safety.

Drilling with robotic precision and in any orientation. With optional marking and tapping tools also available. A true multi-functional and flexible solution for your steel shop.

The robot is laser calibrated, which gives it unmatched accuracy for any of your 3D shapes. The system can be equipped with high speed plasma, and high precision oxy-fuel cutting.

MIG or MAG welding process combined with a robot ensures highly consistent welds. Weld quality can be proved with data logs gathered in over 30 years.

With automatic tool changers for welding, drilling, tapping and the possibility to random place your unique products in its large work-area. By placing the robot on a track it can handle your most extreme product lengths, resulting in a total effective working area of >100m2.

A touch screen with a graphical user interface provides your operators easy control. In fact, you will only need one supervisor, reducing your operational costs to a minimum. Your operator and the robot can share their workspace. The latest smart safety systems provide easy and safe access for example loading and unloading. Operator and robot working together.