Experience the versatility of the Spool Welding Station, a cutting-edge solution designed to handle a wide range of pipe spool components. From elbows and tees to flanges and reducers, this advanced station empowers you to tackle diverse welding applications with ease.

Talk to an expert

Automated pipe spool production

High performance and reliability

Automated pipe spool production

High performance and reliability

When it comes to weld quality, consistency is key. The Spool Welding Station sets the standard for delivering precise and reliable welds that meet the highest quality standards.

Equipped with advanced welding technology and automated operations, this station guarantees consistent excellence at every stage of the production process. By utilizing welding data, ZEROGAP seam technology and TIG welding, we achieve superior weld quality.

Experience effortless precise alignment with KRANENDONK's advanced technology for pipe and pipe-spool production. Our innovative ZEROGAP bevel and marking features ensure exceptional fit-up, streamlining operations for high-quality spool production.

Simplifying the fitting process, our Pipe Support, a mobile jack system, effortlessly transports pipe components to the welding clamp. Paired with our Support Trolley, these tools minimize adjustments and maximize accuracy, making fitting easier than ever.

Experience streamlined production like never before with our smart PSWP (Pipe Spool Work Preparation) software. This groundbreaking software eliminates the complexities and overhead associated with traditional methods, revolutionizing your workflow. PSWP simplifies the entire process by automating work preparation, generating bevel and weld parameters based on your 3D CAD models.

By combining it with the Spool Milling Station, it is possible to achieve ZEROGAP welds, making it an even more versatile and efficient solution for pipe and pipe-component assembly and welding. The Spool Milling Station is capable of preparing the pipe ends with the patented male/female bevel shape required for ZEROGAP welding.

This combined solution, known as the Robotic Pipe Shop, offers a seamless process from preparation to final product, enhancing productivity and quality.

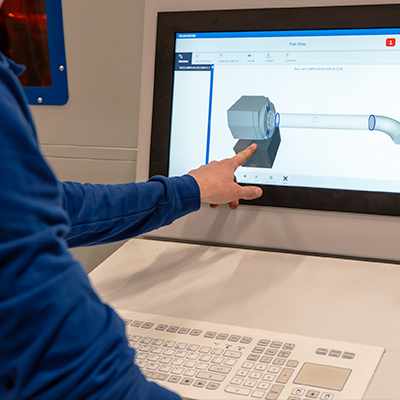

With a user-friendly interface and intuitive controls, the Spool Welding Station is easy to operate, even for users with minimal training. The graphical operator interface simplifies programming and monitoring, enabling operators to navigate the system effortlessly and maximize productivity.

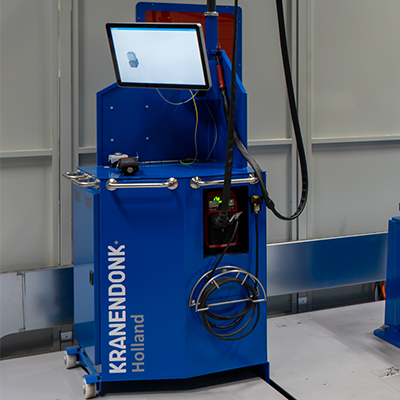

The station is equipped with a tack welding torch and computer interface. It enables precise tack welding by providing guidance to the operator while offering flexibility and mobility. The operator trolley is equipped with all the essential controls and equipment for efficient tack welding and seamless assembly tasks.

Equipped with safety guards and sensors, the station ensures a secure working environment for operators. The sensors detect potential hazards and automatically stop the machine to prevent accidents, ensuring operator safety at all times.

With its versatile capabilities and advanced features tailored specifically for spool production, this innovative station is designed to adapt to various manufacturing settings, making it an ideal choice for your spool manufacturing needs. Our experienced team offers personalized consultations to assess your specific requirements and provide tailored recommendations.

Our experts are ready to assist you with any questions or challenges you may have regarding robotics and automation. Whether you're looking to design and implement a completely new production line or optimize your current processes, we have the knowledge and experience to help you move forward.