International health and safety organizations have recognized the importance of protecting workers from welding fumes. As a result, strict exposure limits have been implemented. These regulations are more stringent for certain materials such as stainless steel. Nevertheless, weld fume from mild steel is now considered carcinogenic.

Welding fume is a mixture of metal and gases resulting from the base metal and filler metal being used. It can contain metals such as chromium, manganese, beryllium, lead, cadmium, aluminum, zinc, and many more.

Many factors influence the worker exposure including the welding technique, amperage, base metal, consumable materials, part geometry and local environment.

Studies have shown that over 90% of weld fume is less than 1 μm in size which is 50 times smaller than the average thickness of a human hair. The small size poses a significant risk to inhalation and requires high efficiency filters to capture.

from the fume, dust and smoke common in welding processes is best accomplished by capturing it at the source to prevent from entering the worker’s breathing zone. The contaminants enter the airways when you breathe in, and pass through the bronchial tubes into the lungs. Due to their microscopic size, these particulates are able to directly enter the cavities in the lungs.

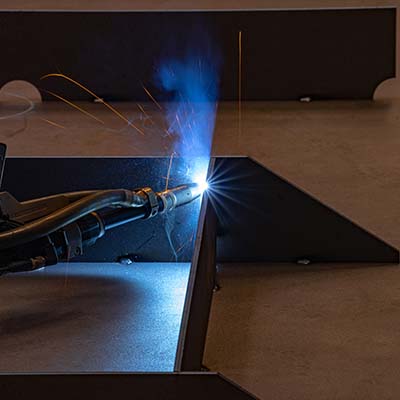

It has been proven that extraction at source is the most efficient method of capturing and removing welding fumes. Using this method, the risk of the welder or operator being subject to hazardous fumes is minimized. Welding torches with integrated extraction allow the robots to work over big areas as well as inside constructions.

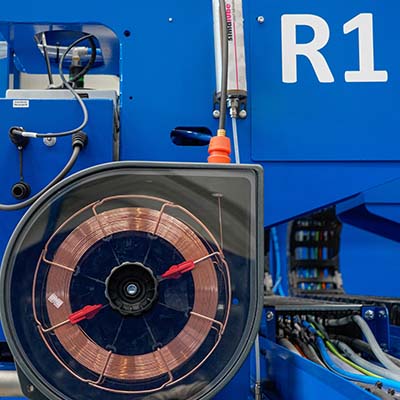

Welding operations using automated welding equipment require careful monitoring. Operators and service personnel overseeing robotic welding equipment can be subject to residual fumes and need to be protected in a similar way to manual workers. In addition to the health risks, uncontrolled weld fume impacts factories by infiltrating machinery or electrical cabinets causing downtime and loss of productivity or accumulating on inventory requiring additional clean up work. This can be done by extraction directly at the torch, or with welding robot hoods or curtains.

Letting the extraction system run when not in use is a big waste of energy. Our fume extraction systems are directly controlled by the robot programs, making sure they do not run longer than necessary. Because the fume is extracted close to the torch, the volume of air needed for extraction is much lower than when extracting from further away. This also saves a lot of energy.