No more rework! Due to the adaptive milling technology, the Edge Preparation System can achieve a perfect radius by adjusting to plate tolerances. This way you no longer have to worry about bottlenecks in production because of time-consuming rework activities. It contributes to the quality of your product with a good coating lifetime.

Maritime Innovation Award winning solution

Adaptive milling technology

Always a perfect plate edge radius

No more rework

IMO PSPC compliant

Maritime Innovation Award winning solution

Adaptive milling technology

Always a perfect plate edge radius

No more rework

IMO PSPC compliant

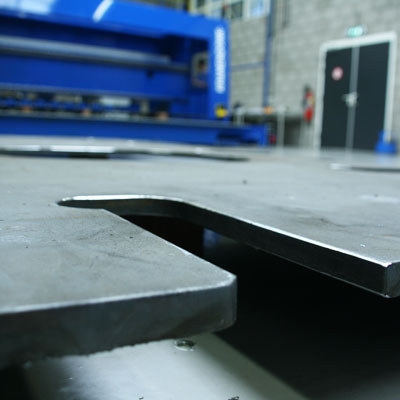

The Edge Preparation System combines proven CNC technology with a state-of-the-art force controlled milling system. The system machines both sides without turning of the plate. Advanced software and a touch screen makes sure that operation is easy. The Edge Preparation System uses a force-guided milling head that is able to move in three orientations. With this adaptive milling technology, the machine mills a constant 2 mm radius (2R) to any plate contour.

Plate tolerances provide a unique challenge. The temperature difference and internal material stress (impacted by plate cutting process) impact the accuracy of the plate size and shape. Coping with these deviations demands a certain level of intelligence when implementing automation. Due to the adaptive milling technology, the Edge Preparation System can achieve a perfect radius by adjusting to plate tolerances. This way you no longer have to worry about bottlenecks in production because of time-consuming rework activities. It contributes to the quality of your product with good coating lifetime.

Automated tool changing maximizes productivity. Different milling heads are available and can be changed automatically by the system itself.

Handling time is reduced by smart pneumatic pin beds that lift the plates and eliminate the need for flipping plates with an overhead crane.

The manual grinding and milling of steel plates is a tough and dangerous job. With our edge preparation system, the opposite is true. A large touchscreen with graphical user interface makes the system easy to control by just one operator. The interface is fully independent of language. The system features predefined safety zones. In this way, the operator is able to safely monitor the process and load/unload while milling takes place. Not only saving hours of manual labour, but also preventing injuries and accidents.

To improve the quality of coatings in shipbuilding, IMO PSPC demands the preparation (rounding) of plate edges. Automation of this process requires an adaptive machine that perfectly follows plate contours. Our Edge preparation system meets this demand. The machine prepares edges of plates for coating with 2R grinding, according to the latest PSPC regulations.

The Edge Preparation System was awarded with the Maritime Innovation Award.

The smart adaptive force controlled milling head perfectly follows any contour and mills a consistent 2, 2.5 or 3mm radius. This gives a constant quality without the need for rework.

Advanced software takes care of all programming tasks. This is done based on the same files used by CNC plate cutters, so the system can directly start in your yard. Easy as that.

Steel plates need to have a minimum 2 mm radius on the edges to prevent coating failure. The Edge Preparation System fully automates this grinding process, reducing your labor costs.

Eliminate rework and enhance quality with adaptive milling technology, while meeting IMO PSPC standards. This system is designed to streamline your workflow, prioritizing efficiency, safety, and precision in edge preparation. It's especially beneficial for industries that demand high precision in plate processing, improving coating quality and overall workflow efficiency.

Our experts are ready to assist you with any questions or challenges you may have regarding robotics and automation. Whether you're looking to design and implement a completely new production line or optimize your current processes, we have the knowledge and experience to help you move forward.