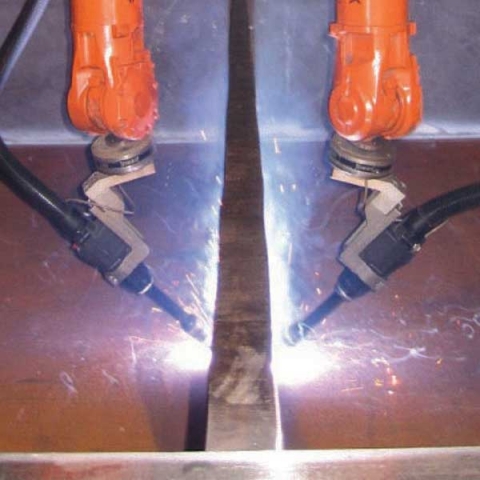

The beam welding gantry provides flexible welding of stiffeners and end plates to large sized beams. A travelling portal suspends one or more robots. While the robot is welding on one part, operators can assemble and tack weld beams elsewhere.

Automatic beam stiffener welding solution

High quality and throughput

Automatic beam stiffener welding solution

High quality and throughput

In offshore construction, most beams are reinforced using stiffener plates and end plates. Since no product is same, robotizing this welding process requires a flexible solution. KRANENDONK's beam welding systems are equipped with intelligent software that enables a continuous flow of non-repetitive products. With the RinasWeld software, the required information is retrieved directly from 3D CAD model including your own predefined weld data.

KRANENDONK's beam welding solutions automatically weld stiffeners to beams. Intelligent software gives flexibility for continuously changing designs.

Seam tracking and automatically applied predefined weld data ensure highly consistent welds. Weld data can be logged for quality purposes.

The optional SAW welding process guarantees thick welds with robotic precision. This gives enormous freedom in heavy steel welding.

A touch screen with graphical user interface provides easy control. To operate the system, only one supervisor is needed, reducing operational cost. Based on 3D CAD, RinasWeld generates collision free robot paths and takes care of all robot programming. This reduces time required for work preparation.

With safety sensors and a covered track, the operator and robot can share their workspace. In this way, the welding process can be monitored closely.