Investing in robot technology has a clear purpose: increasing your competitiveness. The value of your robot system is not made on the day it is purchased, but in the years of reliable production after that. Therefore, it is essential to keep the system and its operators in shape. Our customer support engineers have identified key factors to make the most of your robot production line. These will help you to reach maximum productivity and profit, to make more money with your robot system.

The value of the robot is not made on the day you buy it, but in the years of reliable production after that. Robots are advanced pieces of equipment, but - like any other machine – they need regular maintenance to stay in top condition. Scheduled maintenance to the robot system reduces downtime to a minimum: the maintenance will pay back for itself! We have robot systems running in the field for 20 years, still reaching their productivity goals. Taking maintenance seriously may be the most important factor the make money with your robot system.

Today’s robot lines are easy to control. But when something unexpected happens, it is good to have background knowledge about the robots and the way they behave. Only trained people should operate the robot system. They will know what to do in unexpected situations, and can discuss with our customer support department to quickly resolve problems.

A robot cell should never be considered individually. Surrounding processes are at least as important. In fact, implementing robotics can have an impact on complete company processes: from design and engineering to planning and quality control. To make the most of your robotic production system, all these surrounding processes should be taken into account.

Improving productivity does not stop with robotic automation. Technological or economical developments can affect your process chain or product / volume mix. As a result, you can always keep improving in various production processes, which also includes a robot line. Ongoing digitization in industrial automation lends itself great for analyzing your production.

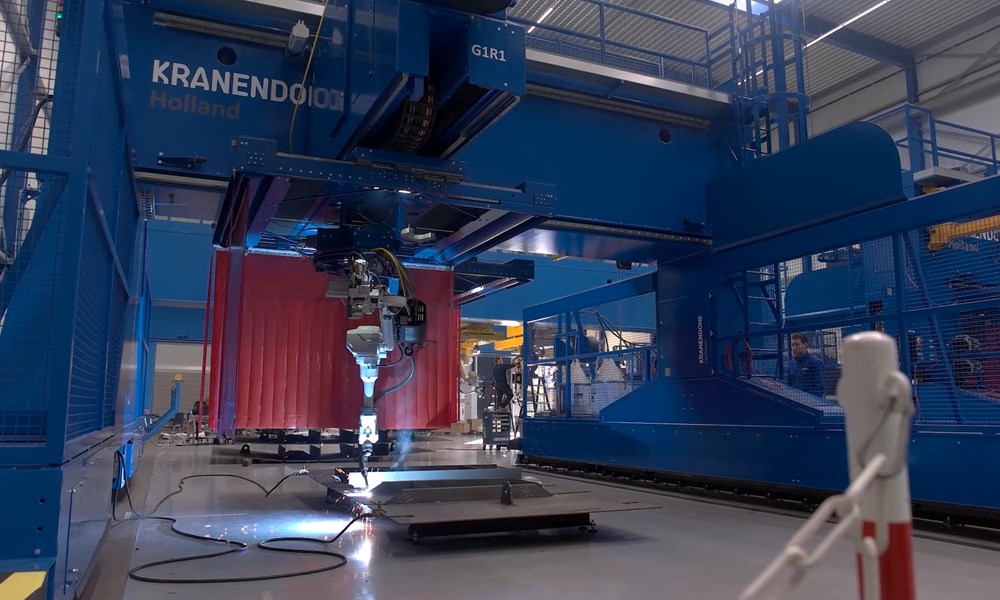

At KRANENDONK, we are here to support your during the lifecycle of your robotic equipment. With comprehensive services by our Customer Support team, you productivity is maintained over many years, to gain maximum return of your investment in robot technology. Contact us.