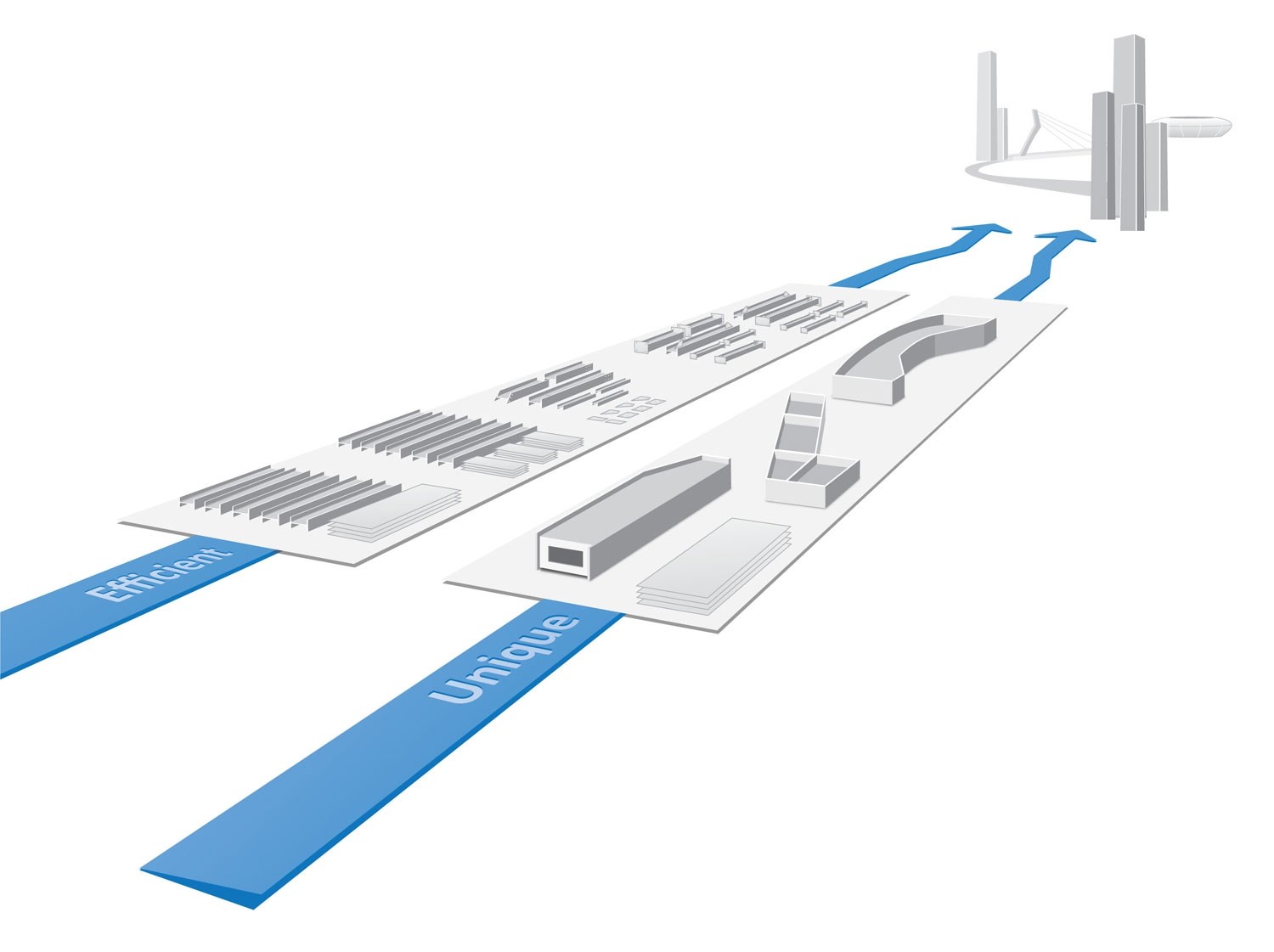

We are leading the robotic revolution in structural steel. KRANENDONK delivers highly connected and adaptive robot lines, which can handle your one-piece production flow. Intelligent robot welding and cutting will give you the smart factory of the future.

When building steel structures, processes have to be aligned to deliver projects within time and budget, preventing delay during assembling. KRANENDONK offers advanced robotics to automate key parts in your process chain. Working for leading steel construction companies, we are often involved in consulting new automation plans.

Since 1983, KRANENDONK is the leading robotics supplier for non-repetitive production. Our smart robots can deal with continuously changing designs, without the programming overload. We can achieve this with smart sensors and software. See our product overview below, or talk to us about your requirements.