RinasWeld generates robot welding programs based on a 3D CAD model. It takes away the programming overload, enabling non-repetitive robotic production. When dealing with continuously changing designs, RinasWeld is your solution.

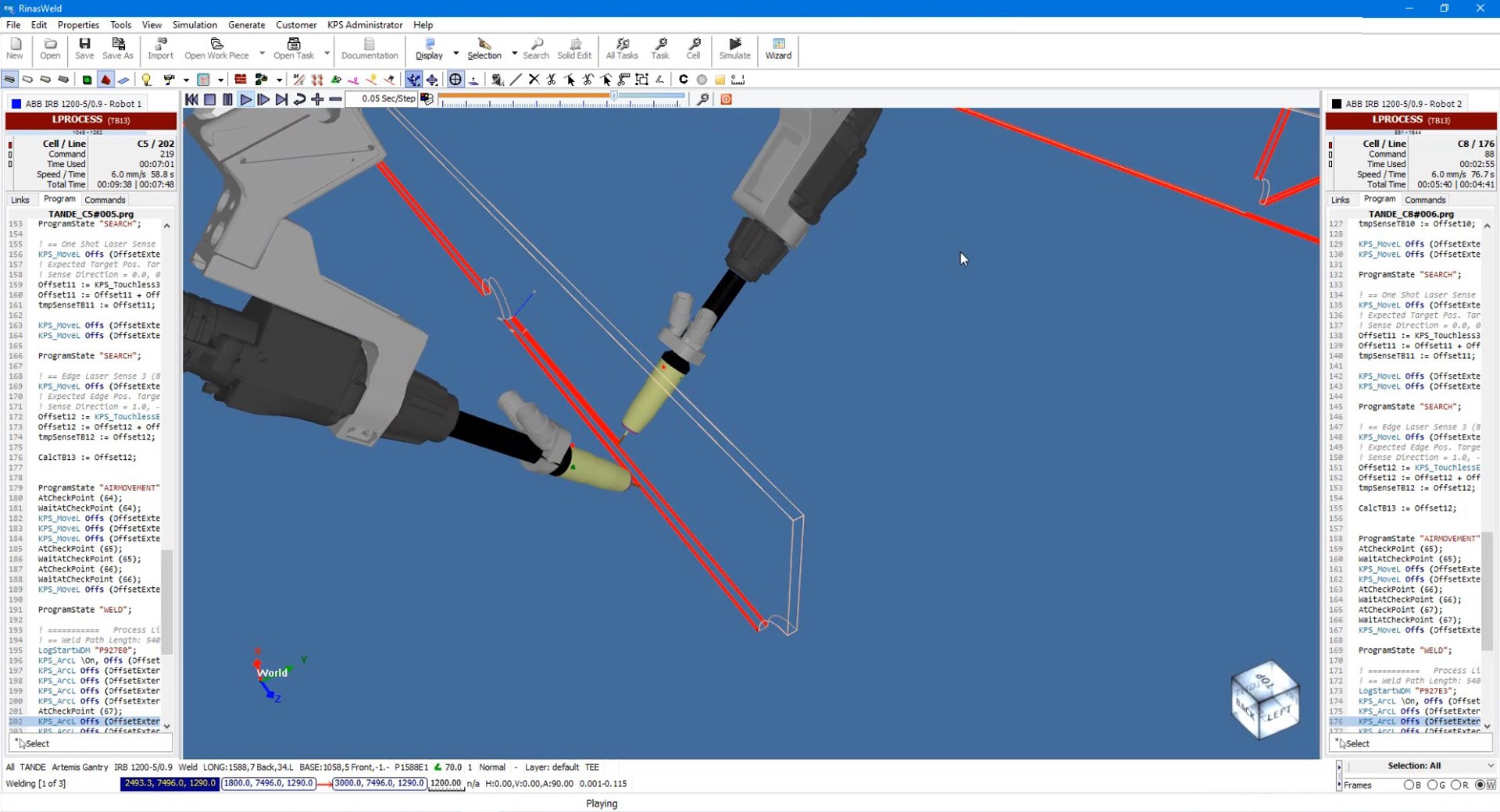

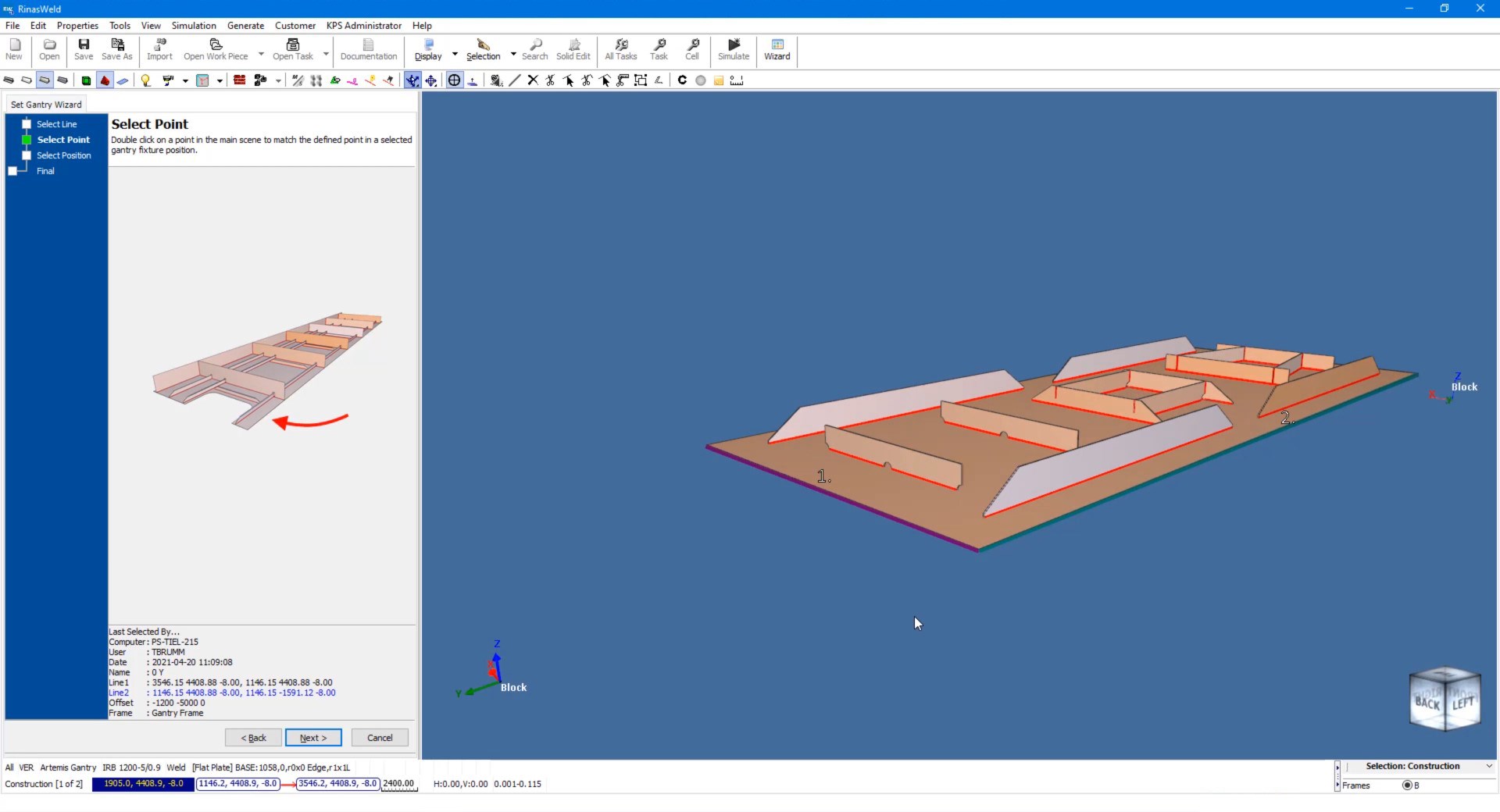

RinasWeld takes a leap forward from traditional robot programming methods, by effectively taking all programming overhead away. You only select the 3D CAD model of the product, after which the software will identify where and how to weld. Smart anti-collision lets the robot make maximum use of the available space, so welding in tiny spaces is no problem. With these intelligent features, RinasWeld is the most advanced connection between 3D CAD and robotic welding.

The software will determine automatically where the welds need to be, how the robots can reach these places, and what parameters should be used for each weld. It means that the software will pick the right WPS from a database of approved weld parameters. If you require, this database can be certified to your quality norms.

We interface with all major 3D design software solutions. You just export the 3D file as a generic format and send it to RinasWeld.

Being used with leading global manufacturers, our RinasWeld software is proven in industries like shipbuilding, steel construction and heavy welding.

We integrate with popular 3D Design software: Intergraph-Smart3D, Aveva-SmartMarine/Tribon/Bocad, Tekla Structures/StruCAD/X-Steel, SSI-ShipConstructor, Nupas-CADMatic, Sener-Foran, and other CAD software that produces any of these exports: .ATX, .STEP, .IGES, .IFC.

With RinasWeld, your robots will reach high productivity in non-repetitive processes. In typical case, we reach well over 90% arc time. All with continuously changing products. As the operator, nor the work preparator, needs to make and check the robot programs, each product can be different resulting in world of opportunity for manufacturers.

After importing your 3D CAD model, RinasWeld retrieves the needed data and automatically generates all production data for robot welding. If desired, the robot program can be simulated for your reference, but this is not necessary. At the shop floor, the operator only needs to select the program to start production. In any welding situation where production is non-repetitive, RinasWeld deals with the programming.

Independent research shows that RinasWeld is a unique method for small batch and single piece robotic (welding) automation. Read more about the usage of RinasWeld in the case from the University of Wollongong. We have a research paper from the University available for you to study.