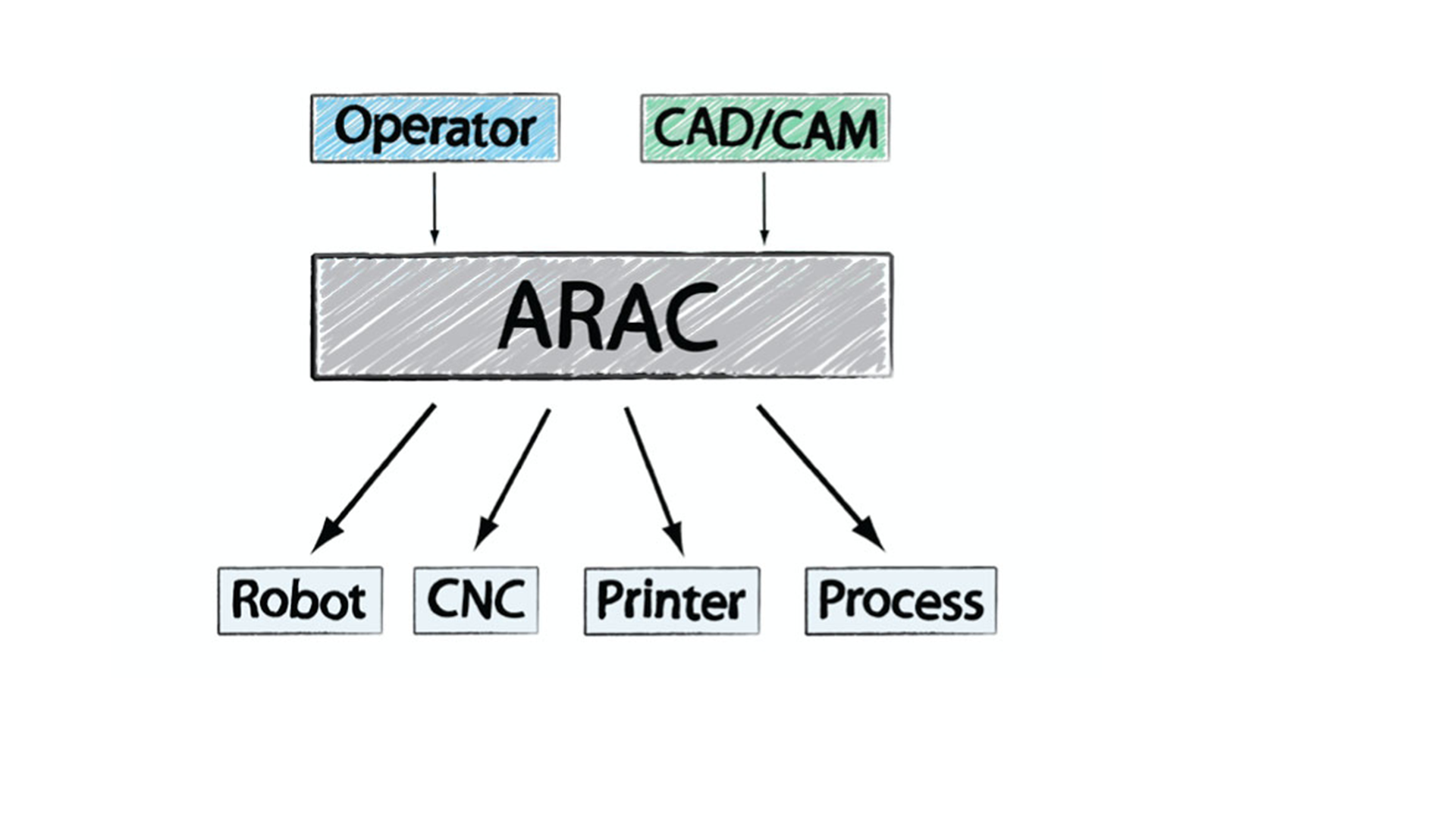

Robots are accurate, fast and do not need a break. The only deficit: you have to tell hem exactly what to do. At KRANENDONK we think the programming should be easy and fast. Besides that, the robot should adapt its robot program when deviations in the product occur. Our ARAC 5 shopfloor control system software is able to do so.

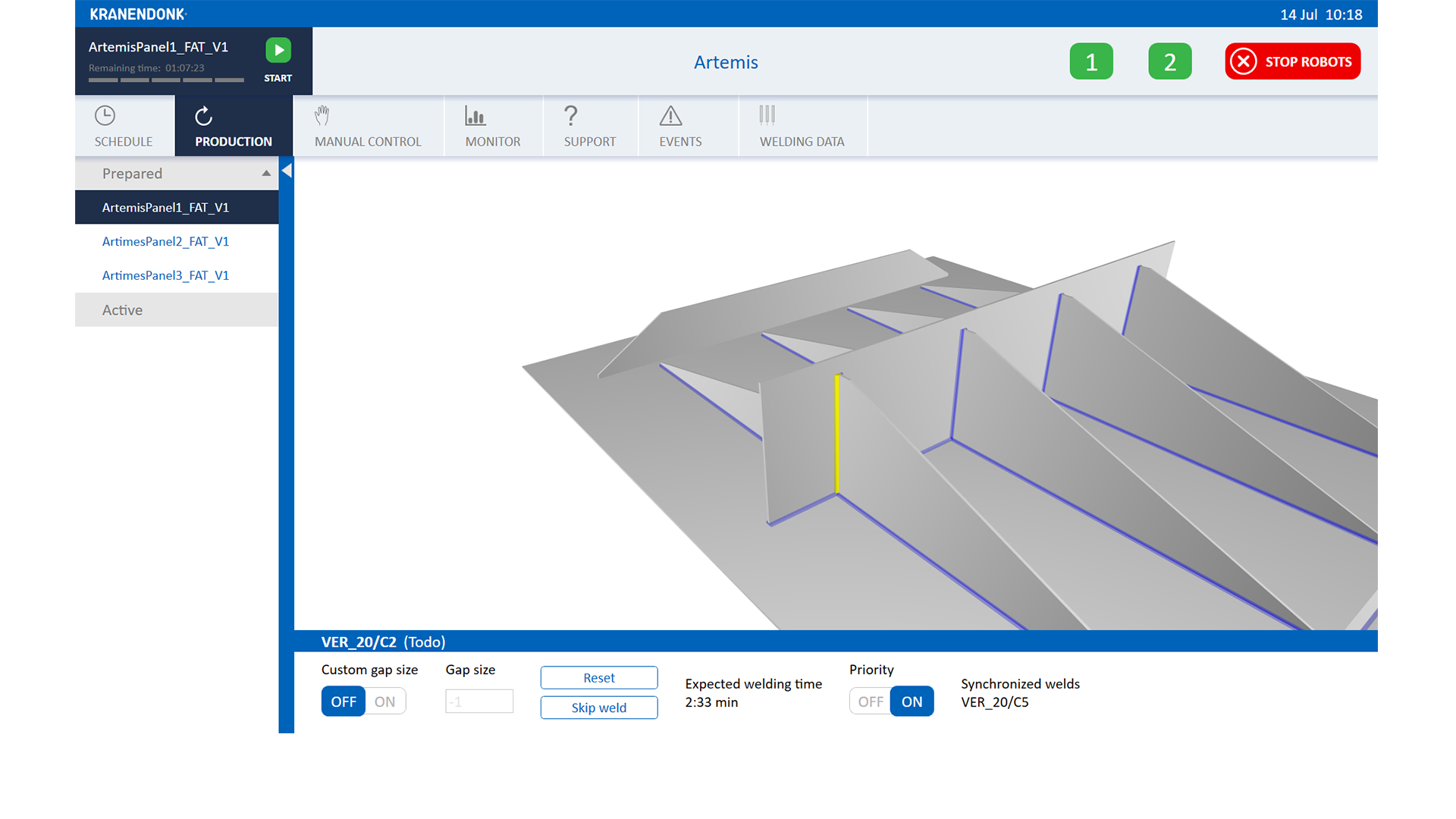

ARAC 5 is the primary software used at the shopfloor. It's designed to control machines in an efficient and user-friendly manner.

ARAC stands for Arithmetic Robot Application Control and it controls the complete application.

Throughout its lifetime, ARAC has gone through many versions and updates, starting with ARAC 2 in the late 80s which ran on a DOS operating system. The latest version, ARAC 5, was released in 2020 and is designed to run on Windows 10.

ARAC 5 generates robot programs based on the input of just a few parameters. Such as the length and width of your product. It means that all programming overhead is taken away. This way, you can realize a robotized non-repetitive production flow, with continuously different products. A big step forward from the traditional repetitive robot lines!

Tolerances in steel profiles and steel pipes are common in the industry. When tolerances are not taken in account, misfits may occur when assembling the several pieces. To prevent this from happening, the ARAC software first measures the material. Using this information, an individual cutting program (robot path) is made for each production step. Even the deviations of connecting steel profiles - for example a connecting beam in a large construction - can be taking into account.

A system can have multiple workstations. This is mainly done for practical reasons, because the operator needs to give input to the system and have an overview of the system at the same time (CE regulation). As soon as the footprint of the system expands, and the operator must give input at several locations in the system, multiple workstations will be recommended.