In today's fast-paced industrial landscape, speed and quality are paramount. Our new Robotic Pipe Shop is specifically designed to meet these demands head-on. From bevel creation for optimal fit-up to consistent, high-quality welds, this solution streamlines processes, reduces errors, and delivers exceptional results, ensuring you stay ahead.

Talk to an expert

From carbon steel to stainless steel

Automated pipe spool production

Flexible production

From carbon steel to stainless steel

Automated pipe spool production

Flexible production

Experience a game-changing approach to pipe spool manufacturing as we revolutionize the industry. With our advanced solution, achieve significant time savings, reducing hours of work to just minutes. Rest assured, our streamlined process doesn't compromise on quality, delivering exceptional results every time.

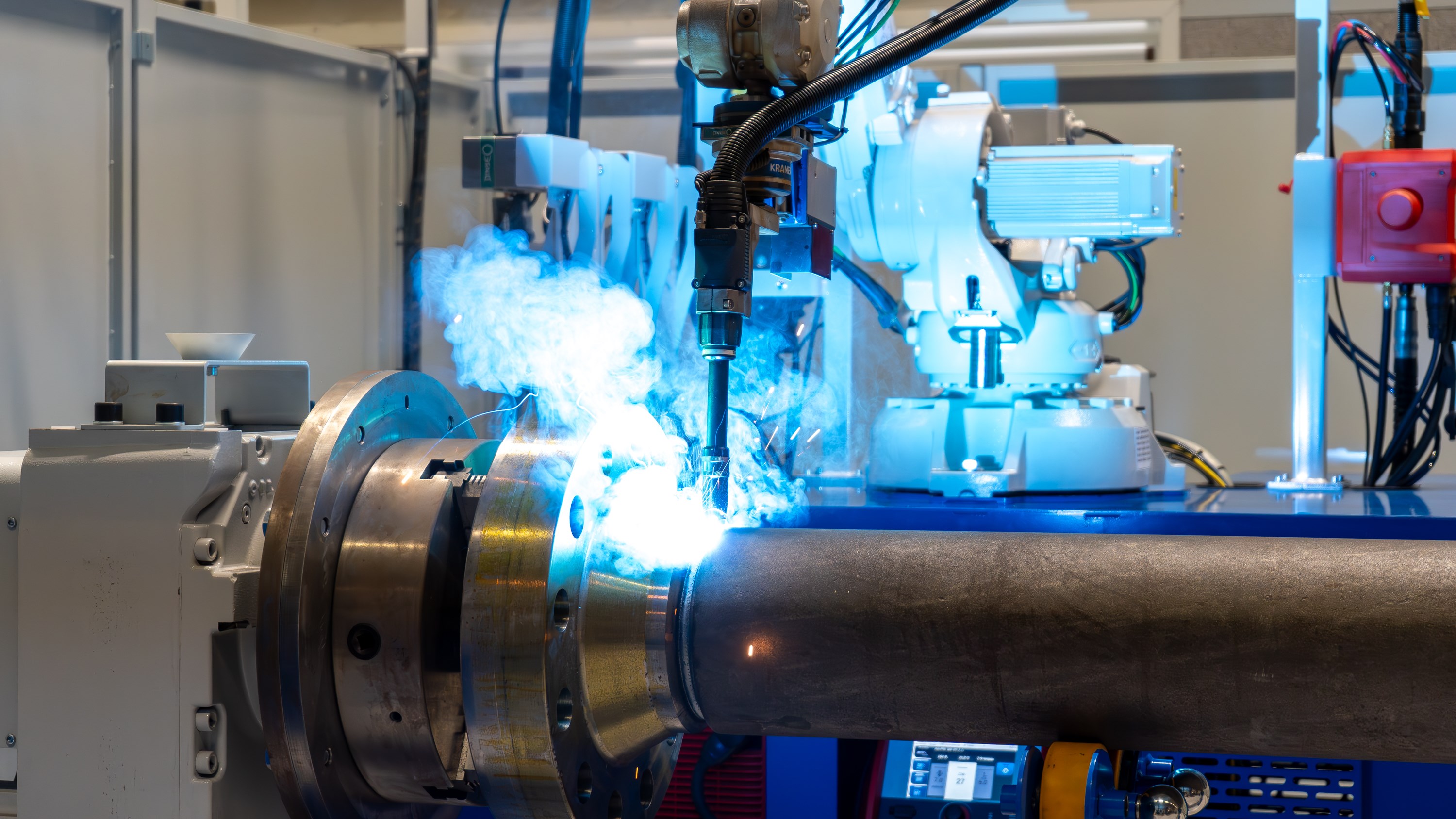

Our cutting-edge technology streamlines the fit-up process, ensuring precise alignment and eliminating costly adjustments. Combined with advanced welding techniques and automated operations, our solution delivers superior weld quality that meets the highest industry standards.

Combining the milling and welding station creates an integrated powerhouse, streamlining production and maximizing efficiency. What sets us apart is that our advanced system is designed to be user-friendly and intuitive, eliminating the need for highly skilled welders.

With user-friendly interfaces and intuitive controls, our system ensures ease of use for operators at every step of the manufacturing process. Even users with minimal training can quickly adapt to the Robotic Pipe Shop and confidently operate it, unlocking its full potential.

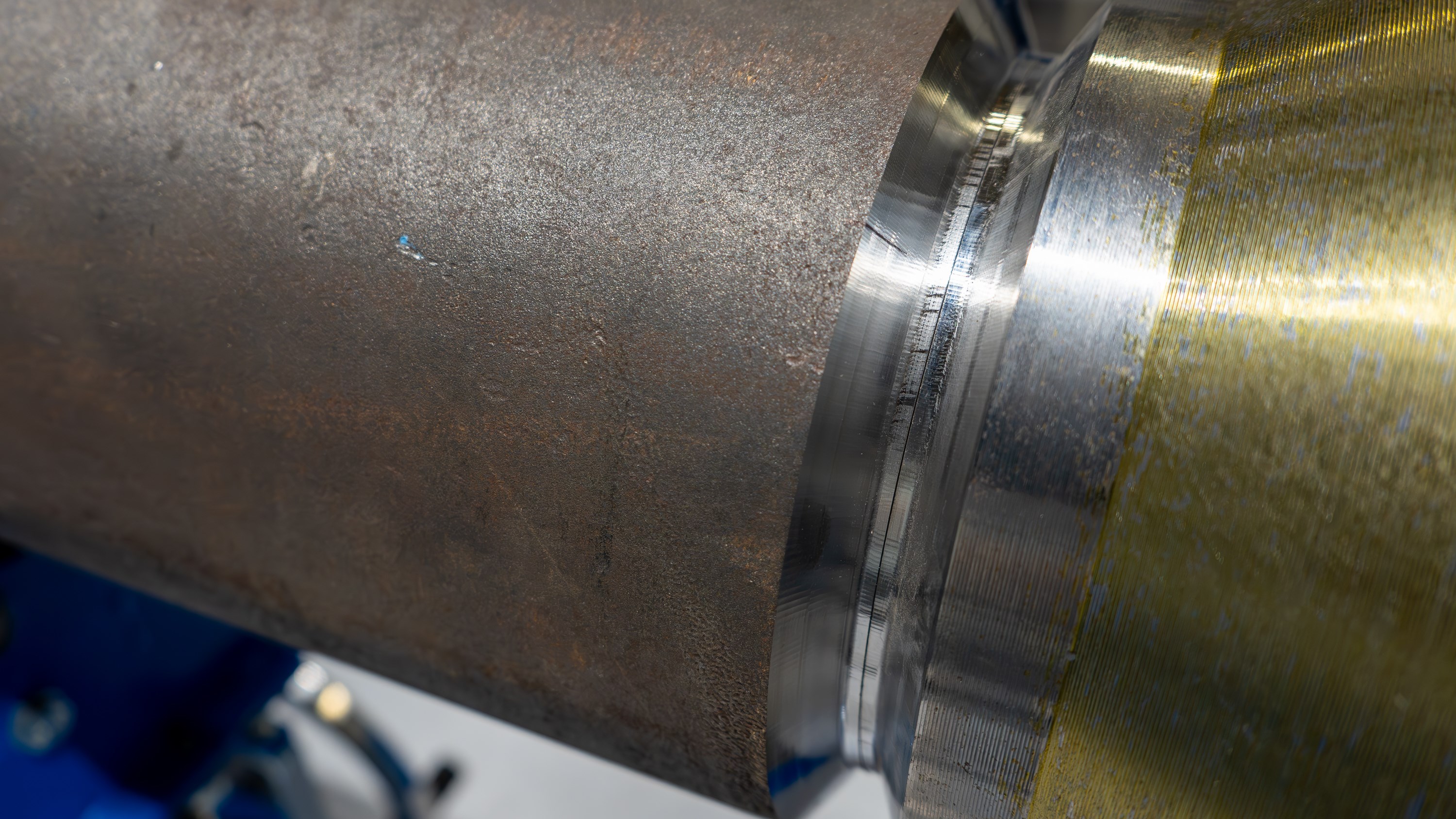

What sets us apart is our patented technology known as ZEROGAP, which creates a unique male-female bevel connection. This technology ensures impeccable alignment and facilitates easy fit-up for welding operations between pipe-components.

The concept of the ZEROGAP is rooted in its name - zero gap. It means that the male and female components fit together so closely and precisely that no space, or 'gap', remains between them. This tight, seamless fit ensures a high degree of alignment and positional accuracy, which significantly simplifies the welding process.

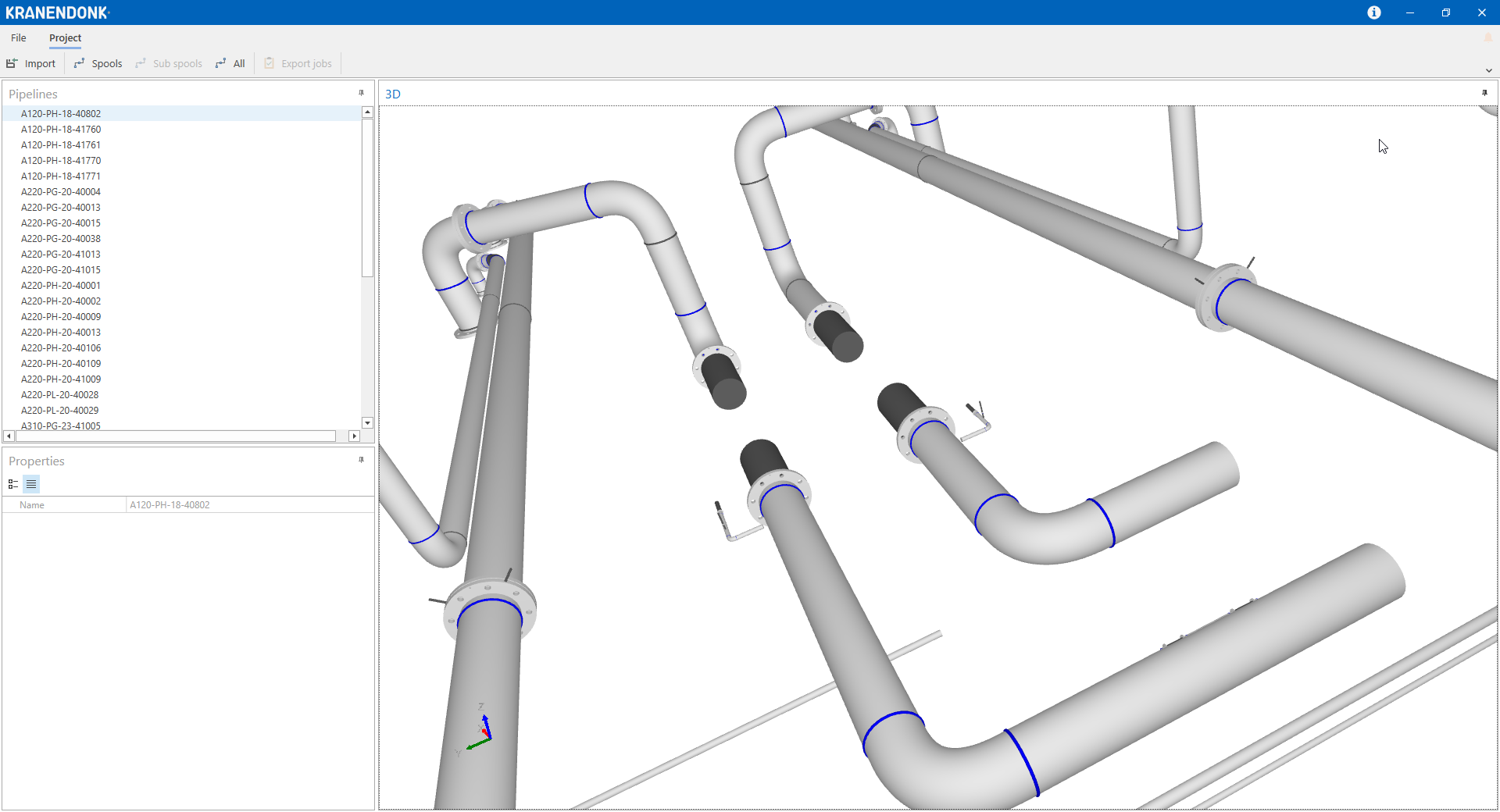

We thrive on turning the impossible into reality and ensuring reliable production planning. Our remarkable capability lies in effortlessly importing 3D files into our KRANENDONK software and automatically preparing them for seamless production.

Our intuitive PSWP software simplifies the process by automatically conducting a comprehensive analysis of component types, materials, and parameters. This allows us to pre-design the essential bevels and welds, guaranteeing the production of exceptional quality spools.

When it comes to weld quality, consistency and precision are paramount. Our solution not only sets the standard for delivering precise and reliable welds but goes beyond by eliminating tolerances and closing the gap for unparalleled excellence.

Equipped with advanced welding technology and automated operations, this shop guarantees consistent excellence at every stage of the production process. By utilizing welding data, seamless ZEROGAP technology, and TIG welding, it facilitates the creation of flawless root passes. The integration of welding data optimizes parameters, while ZEROGAP ensures a seamless fit-up, ultimately leading to superior weld quality.

We have successfully met the rigorous requirements outlined by the internationally recognized NEN-EN-ISO 10675-1:2022 standard for welding procedure qualifications but also apply our expertise according to the ASME norms.

By passing these certifications, we demonstrate our commitment to adhering to the highest standards and providing our customers with exceptional products and services. You can have confidence in our capabilities as we continue to uphold these stringent guidelines and deliver excellence in every aspect of our operations.

By automating repetitive and physically demanding tasks, the Robotic Pipe Shop helps reduce operator fatigue and potential injuries. Operators can focus on overseeing the production process, ensuring smooth operations.

With ARAC 5, operators can rest assured that the entire station is fully controlled and monitored, providing a streamlined and high-quality production process.

With its exceptional capabilities, it can handle pipe sizes ranging from 2 to 16 inches, providing unparalleled flexibility and adaptability to meet diverse requirements.

Understanding the potential of a new system can be challenging. That's why we offer personalized demonstrations to show you exactly how the Robotic Pipe Shop can enhance your operations. You'll see firsthand the user-friendly interface, adaptability, and efficiency of this advanced system in a live setting, tailored to your production environment.

Don't leave it to imagination. Request a live demo today and witness how the Robotic Pipe Shop can revolutionize your manufacturing process!

Our experts are ready to assist you with any questions or challenges you may have regarding robotics and automation. Whether you're looking to design and implement a completely new production line or optimize your current processes, we have the knowledge and experience to help you move forward.