You can reach maximum productivity in the profile cutting shop, by connecting all processes. We supply tailored profile production lines with smart software that can run day and night.

Fast system with high throughput

Automated robot programming

Adapt to profile deviations

Fast system with high throughput

Automated robot programming

Adapt to profile deviations

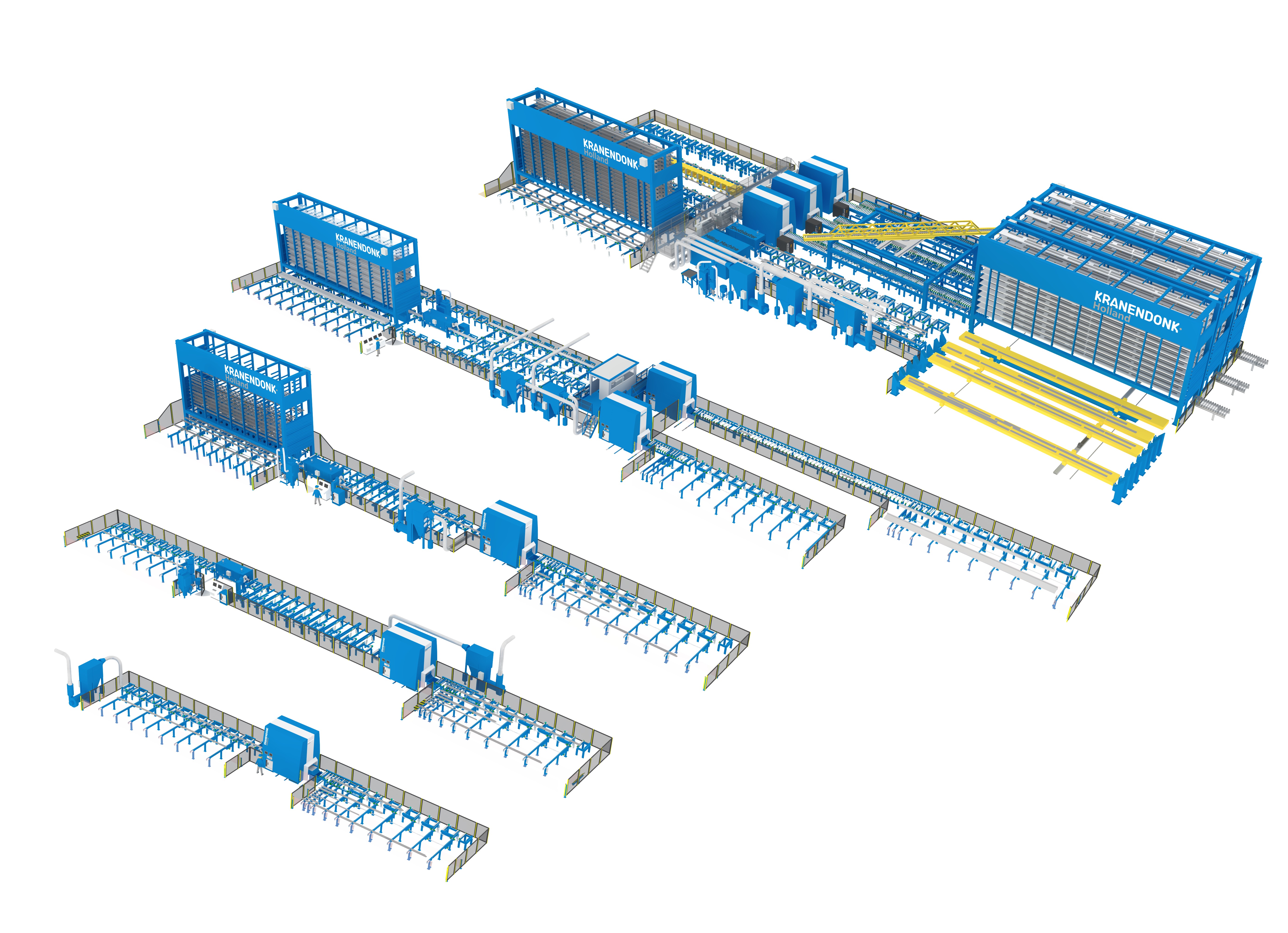

The profile cutting line is a fast and reliable steel profiling solution for your shipyard. You can realize a highly efficient steel cutting shop with integrated buffers and even a high-rise storage. Any 3D shape can be accurately cut with the robot plasma cutter. The system is based on our third generation CCS cutting cell, resulting in a durable profiling machine.

We offer completely automated systems for the processing of profiles in your steel shop. A fully equipped plant features a range of components: robotic cutting cells, logistical equipment such as a high-rise storage and dedicated production software. The machines are cleverly connected and retrieve data straight from CAD.

By using in-flow profile positioning, no repositioning of a stopper or pusher is necessary. This reduces cycle time and leads to an even higher throughput of profiles.

The robot is laser calibrated, which gives it unmatched accuracy for any 3D shape. The system can be equipped with high speed plasma cutting and high precision oxy-fuel cutting.

By measuring the profile before cutting, the intelligent software automatically adapts to deviations in the material. More accurate cuts result in better fitting parts and less rework.

By using in-flow profile positioning, no repositioning of a stopper or pusher is necessary. This reduces cycle time and leads to an even higher throughput of profiles. The robot is laser calibrated, which gives it unmatched accuracy for any 3D shape. The system can be equipped with high speed plasma cutting and high precision oxy-fuel cutting.