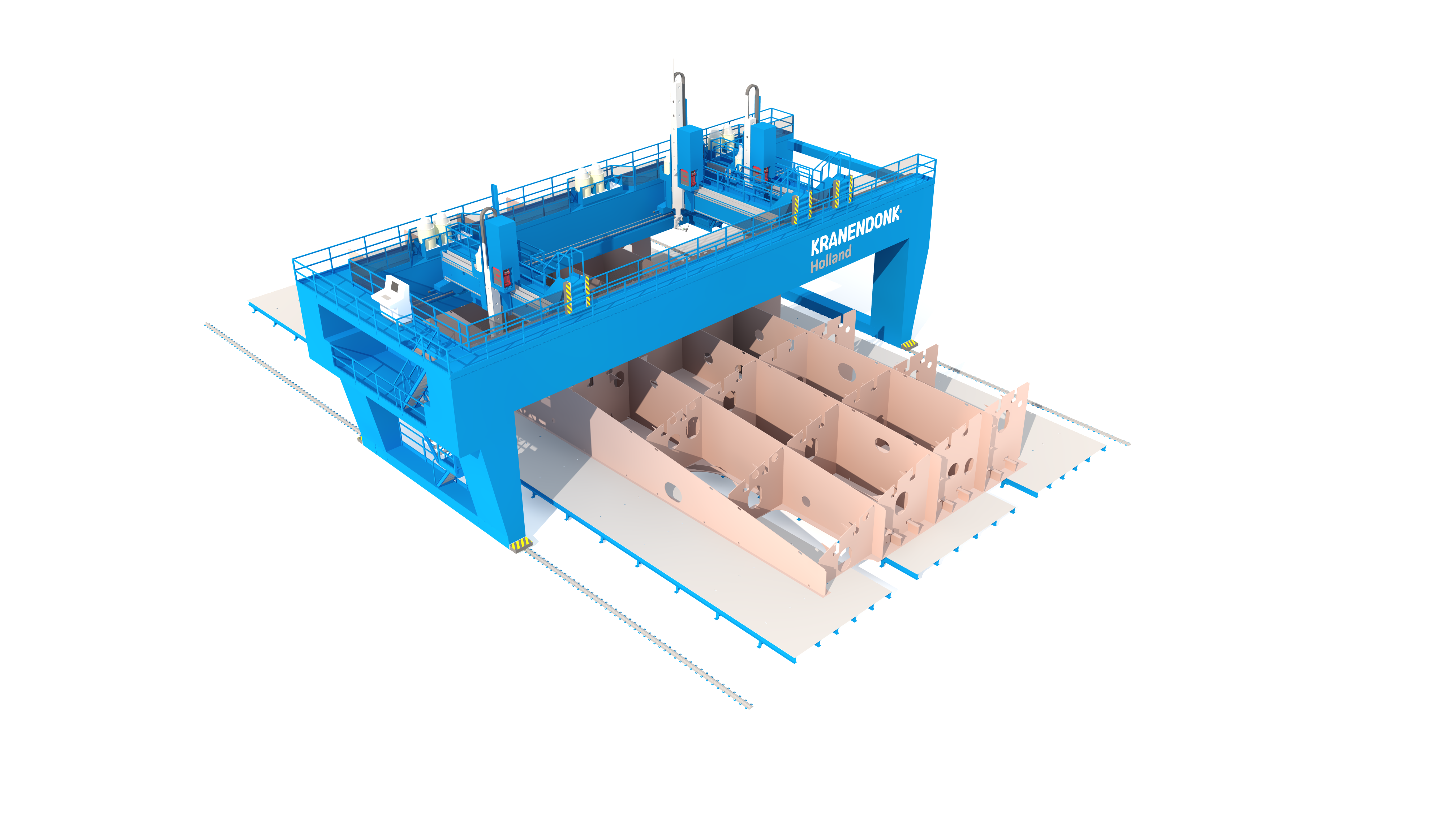

Fully automated welding of large hull sections of a ship. Double hull blocks are giant, one-of-a-kind work pieces, with hard to reach spaces. Suspended into this limited places, smart robots work together and weld without colliding.

Fully automated welding of large hull sections up to 7 meters high

'Hands-off' robotic welding in hard to reach places

Extreme stability, premium quality welds and easy operating

Fully automated welding of large hull sections up to 7 meters high

'Hands-off' robotic welding in hard to reach places

Extreme stability, premium quality welds and easy operating

Welding the double hull of a ship is difficult because of the limited space. KRANENDONK developed a double hull welding line, combined with RinasWeld for automatic operation. The gantry facilitates robot welding of extreme product sizes such as double bottom hull sections of oil tankers and container ships. Small robots are suspended from the gantry to weld in the smallest places, making optimal use of their space.

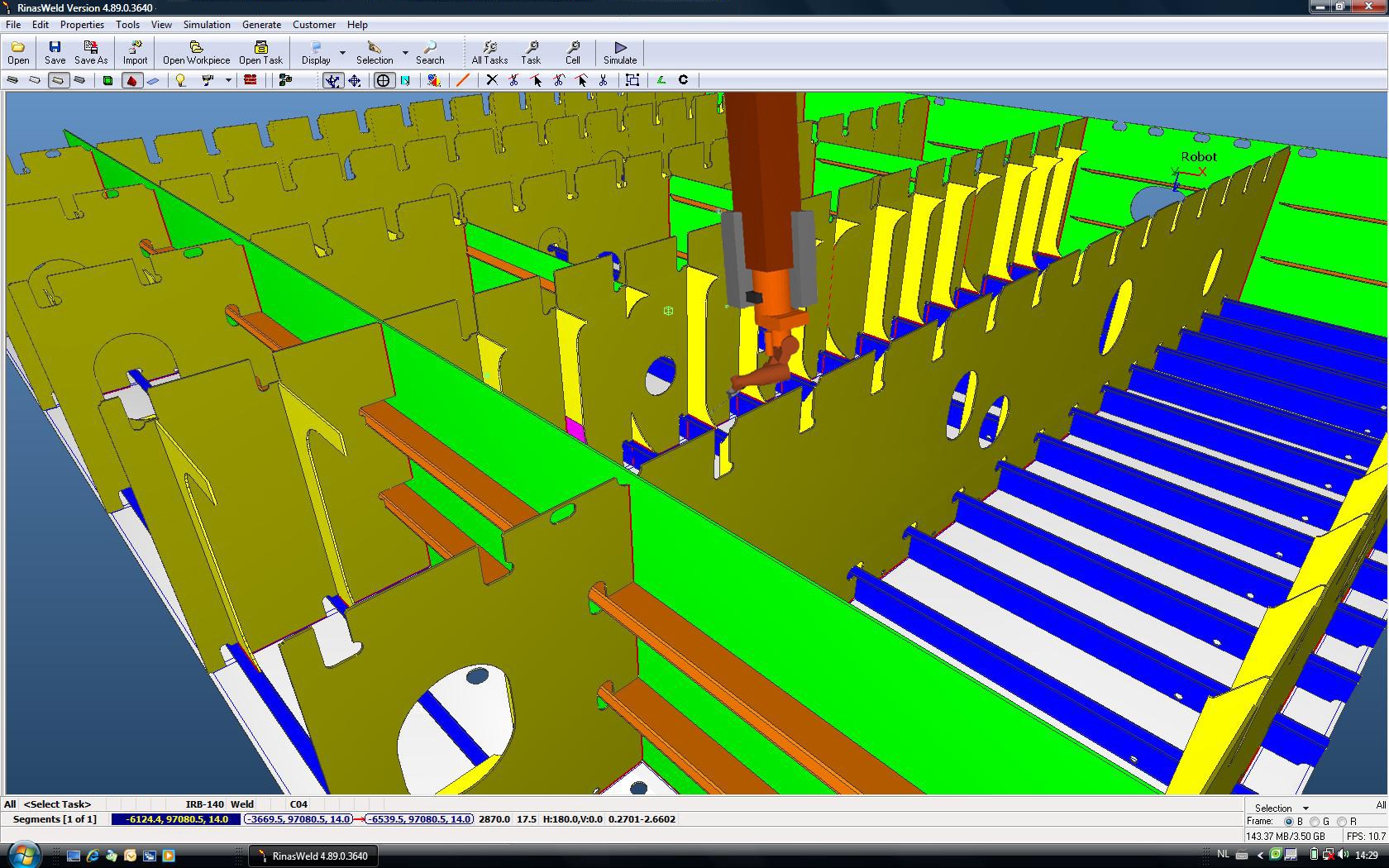

RinasWeld automatically recognizes welds and applies predefined weld data. This results in high quality welds for all kinds of sections and shapes. Thanks to the easy to use graphical user interface, multiple double hull gantries and robots can be operated by only one supervisor. This reduces your operational costs.

Extreme stability

The rigid design of the gantries ensures extreme stability and high quality welding. This accelerates consistency and quality of your one-of-a-kind sub-assemblies.

Depending on the shipyard's capacity requirements, the system is equipped with one or multiple robots. The intelligent RinasWeld software automatically generates all production data based on 3D CAD models and enables multiple robots to work together without colliding. Besides automatic robot path generation, RinasWeld applies predefined weld data, provided by your own experts, for specific corner situations. Independent research has shown that KRANENDONK's concept for double hull welding offers the highest number of welding meters per robot. This powerful software offers easy but advanced offline programming and reduces the time required for work preparation. Setting up a complex block section will only take you minutes.

Based on 3D CAD, RinasWeld generates robot paths and takes care of all programming. This reduces time required for work preparation and gives hours of automated production.

Tiny robots are suspended into the smallest places of a double hull or block section. With RinasWeld, the robots operate independent and follow collision free paths.

The rigid gantry travels across a large work area to access block sections from above. High stability and motion performance give full control over any weld position.