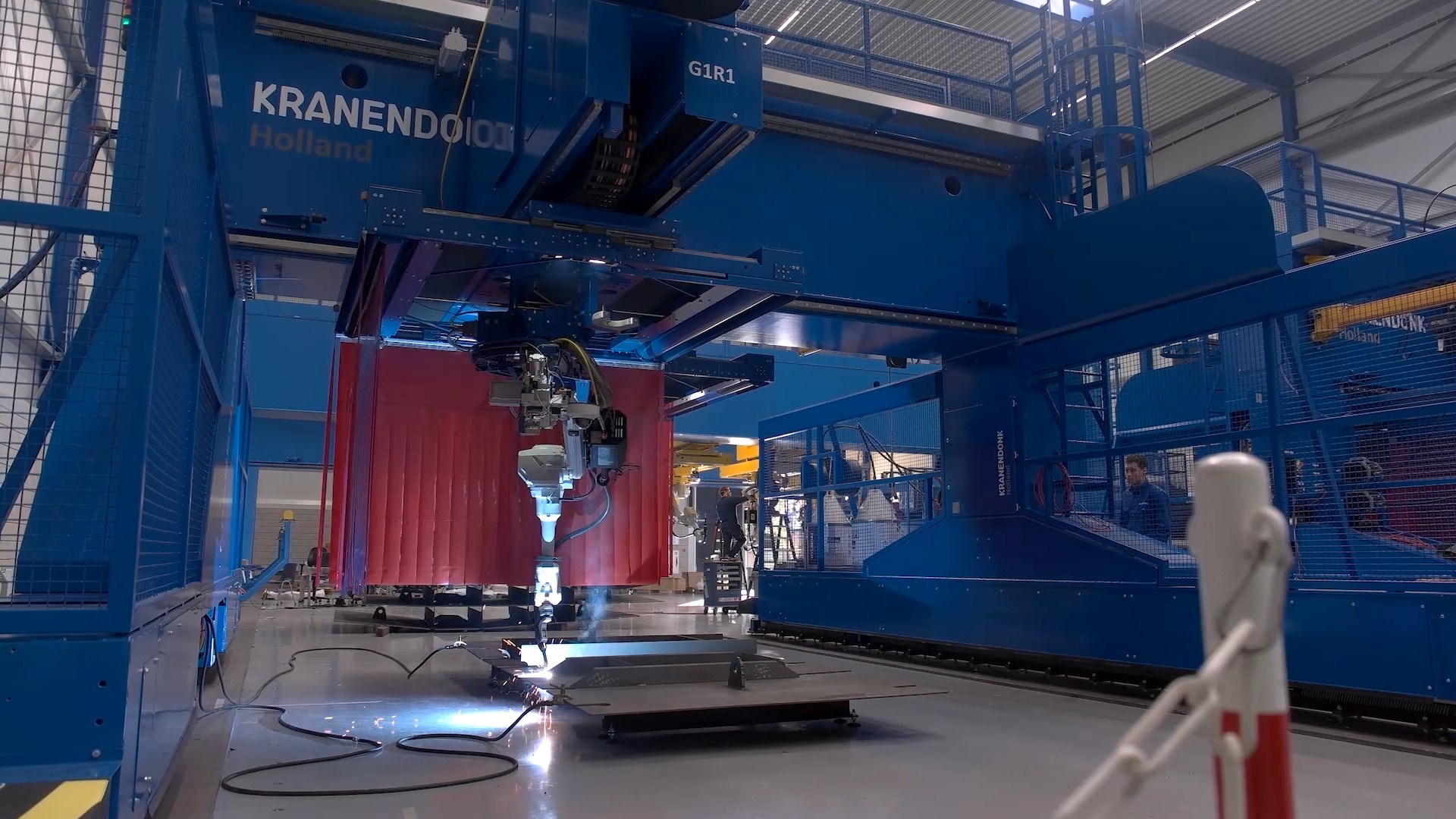

Robots provide an incredible opportunity to accelerate your production. With tailored robot lines, we improve quality and productivity in steel processing industries. This enhances the entire work flow, making your production more efficient and safer and your company more competitive.