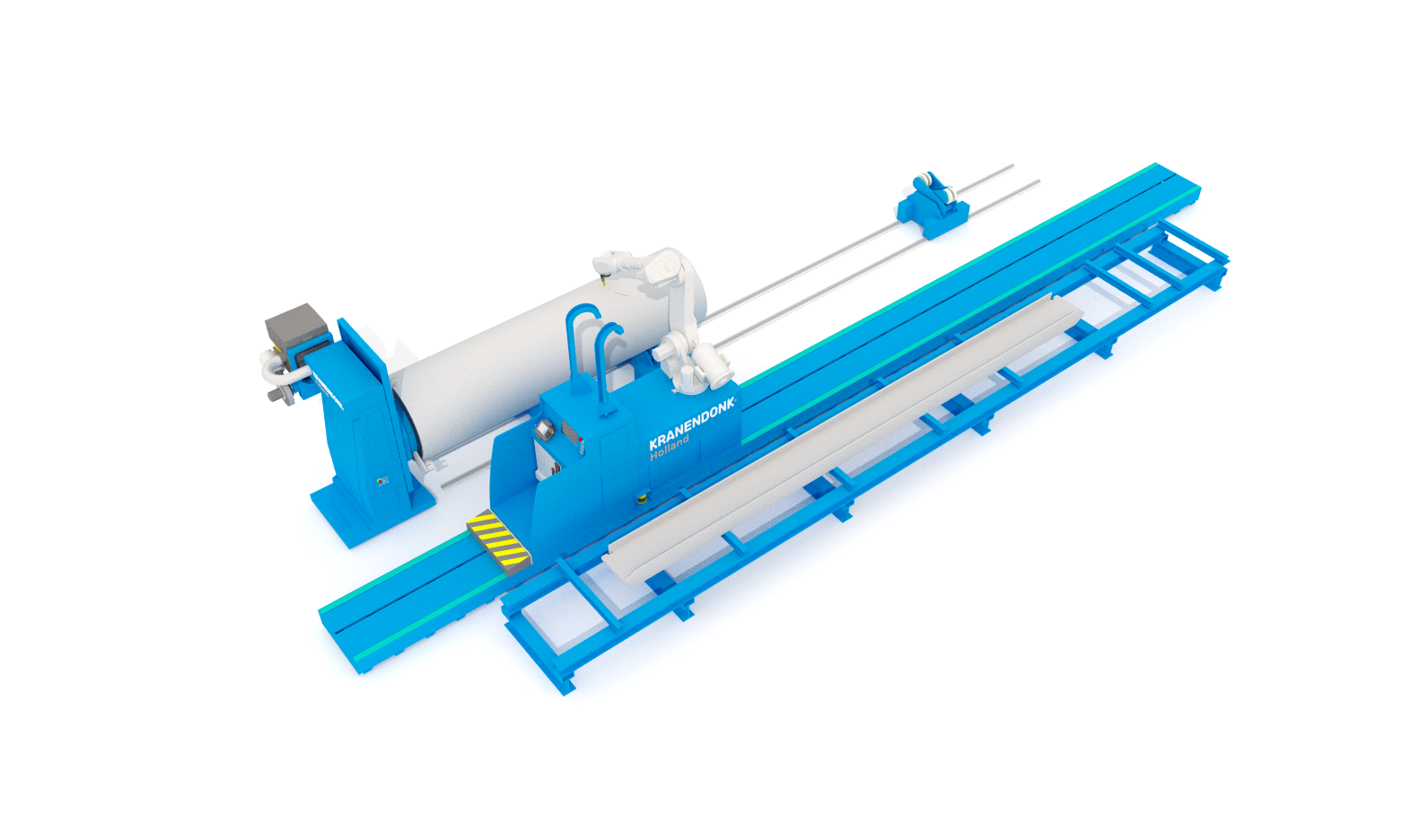

The combined tube and beam cutting cell is the ultimate solution for flexible offshore construction. A continuous flow of production is achieved as the system is able to proceed cutting while loading or unloading takes place at the other side.

For flexible offshore construction

Continuous production flow

Cutting while loading or unloading

For flexible offshore construction

Continuous production flow

Cutting while loading or unloading

It features a large industrial robot with an oxy-fuel and plasma cutting torch. The cutting robot makes all sorts of 3D cuts to both tubes and beams. The floating chuck rotates tubes up to 2.3 meters in diameter with high precision. Special software compensates for deviations in the material to cope with the high accuracy demands in offshore construction.

A continuous production flow is achieved as the system is able to proceed cutting while (un)loading takes place at the other side. The operator is supported in his tasks through a graphical user interface. This ensures flexibility and easy operation of the system. New cuts are added by entering parameters, such as pipe dimension and cutting angle, at the touch screen. Also, a CAD interface can be implemented for a direct data connection.

The robot is laser calibrated, which gives it unmatched accuracy. The results are better fitting tubes and beams, saving you valuable hours on rework and manual welding.

Before the actual cutting, all tubes and beams are measured at multiple points. The cutting path is adapted accordingly, to create better fitting parts for your products.

Tubes and beams are all cut on the same system, offering great flexibility in your workshop. Additionally, the multi-station setup improves your production flow.

Production tasks of the robot are fully automated. Thanks to the intelligent software, the entire system can be run by one operator. With the latest safety systems, the operator and the robot can share their workspace in a cooperative way, the way of the future. This provides easy and safe access for loading and unloading preventing accidents on the work floor.