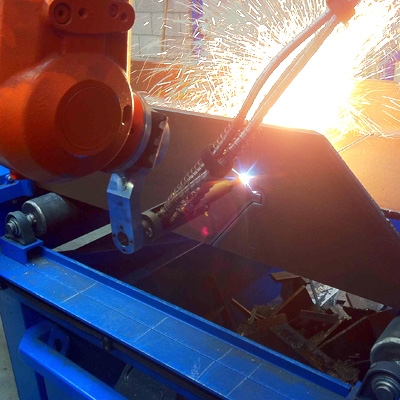

A reliable solution for your beam production. Accurate cutting for all typical offshore shapes, using a large robot. A durable system, producing razor sharp results in harsh conditions. 30 years of steel cutting experience in one solution.

For all typical beams, profiles and shapes

For all typical beams, profiles and shapes

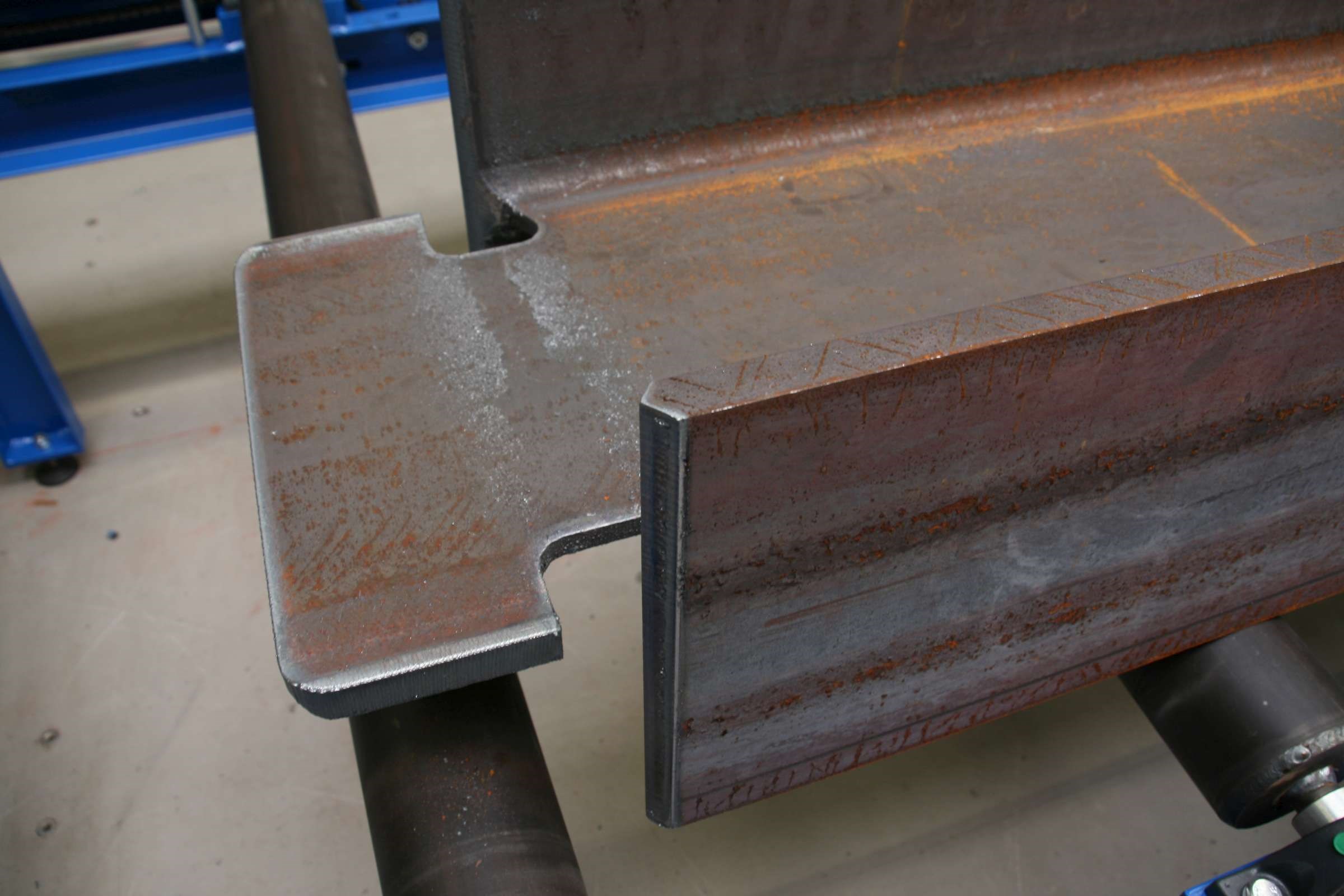

The goal when cutting beams is to create parts that perfectly fit together. This makes the later assembly and welding process quicker and better manageable. To achieve these perfect fits, the KRANENDONK’s robotic cutting systems use real product dimensions, not theoretical data. By 3D measuring each individual beam and adjusting the robot path accordingly, the deviations of the raw material are compensated. Since connections now fit much better, there are significant savings in welding hours as well.

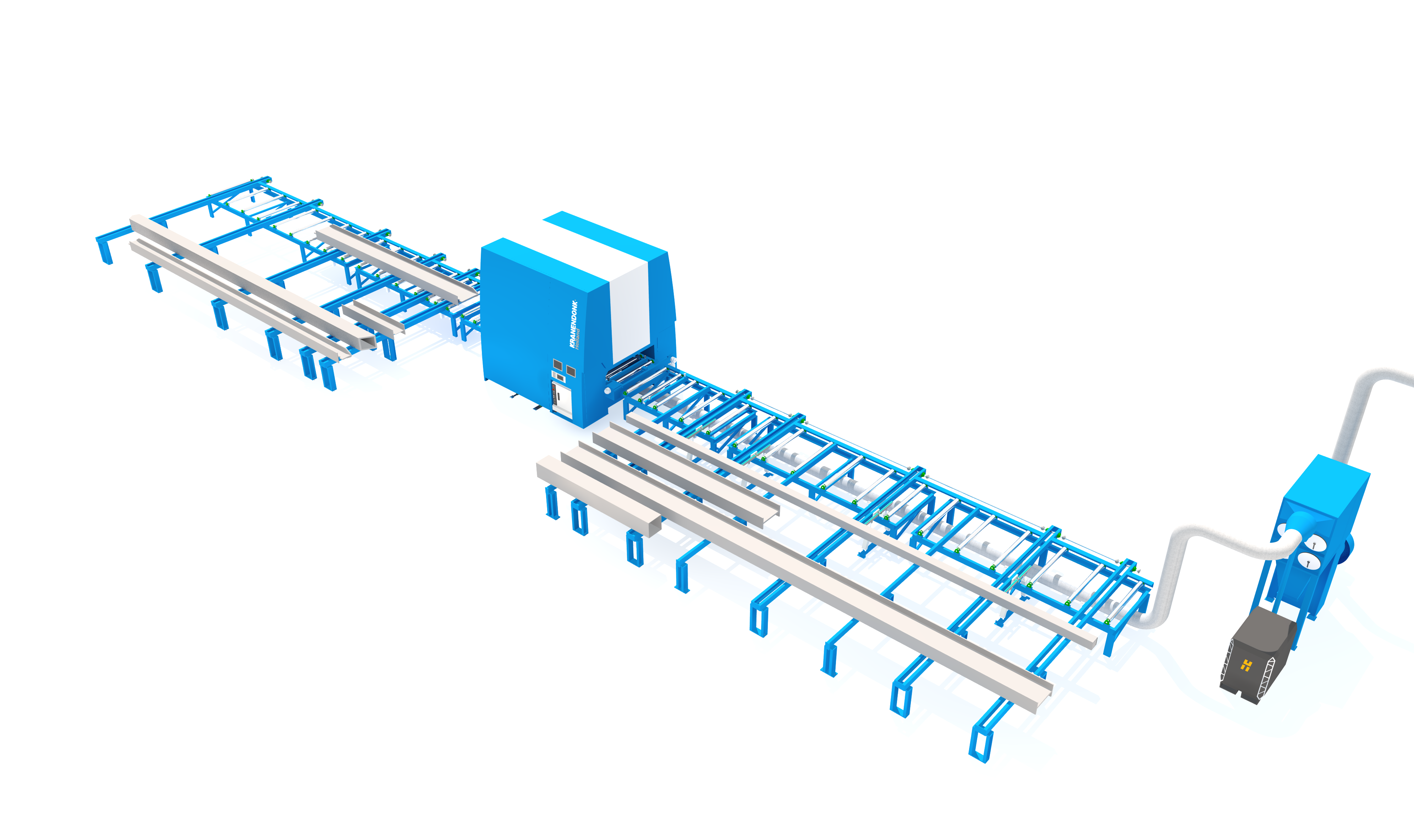

Our CCS cutting system has three unique features. First, smart software is used to adapt the cutting path to deviations in the steel beams. It reduces the gaps when assembling and welding the parts. Secondly, an in-flow positioning system eliminates the need for a length measuring trolley or gripper. This speeds up your process and significantly reduces the need for maintenance. Finally, the CCS cutting system is designed for reliability: all components, wiring and controls are integrated in a single base frame.

By using in-flow profile positioning, no repositioning of a stopper or pusher is necessary. This reduces cycle time and leads to an even higher throughput of beams.

Programming of the cutting system is fully automated thanks to the CAD-interface with nesting functionality. The open software enables the end user to easily create new cuts.

The compact all-in-one CCS cutting cell requires less floor space than conventional systems. Different cutting and marking options can be integrated into one system. Sliders are eliminated by using a fixed robot and in-flow profile positioning. This gives years of reliable production with minimized maintenance and maximized productivity.

The success of our offshore cutting lines is based on our strong connection with the industry. Our current beam cutting cell is already the 3rd generation robotic machine. It holds all the experience we have gained over the past decades. Smart features like in-flow profile positioning, give you better results in the demanding offshore construction business. The rigid design makes it a machine you can rely on.