Combining robot welding and cutting, for ultimate flexibility. Creating and easy to use and reliable operation. Making optimal use of your limited floorspace with this combined beam and tube cutting cell, saving you hours of valuable time.

Combining robot welding and cutting

Combining robot welding and cutting

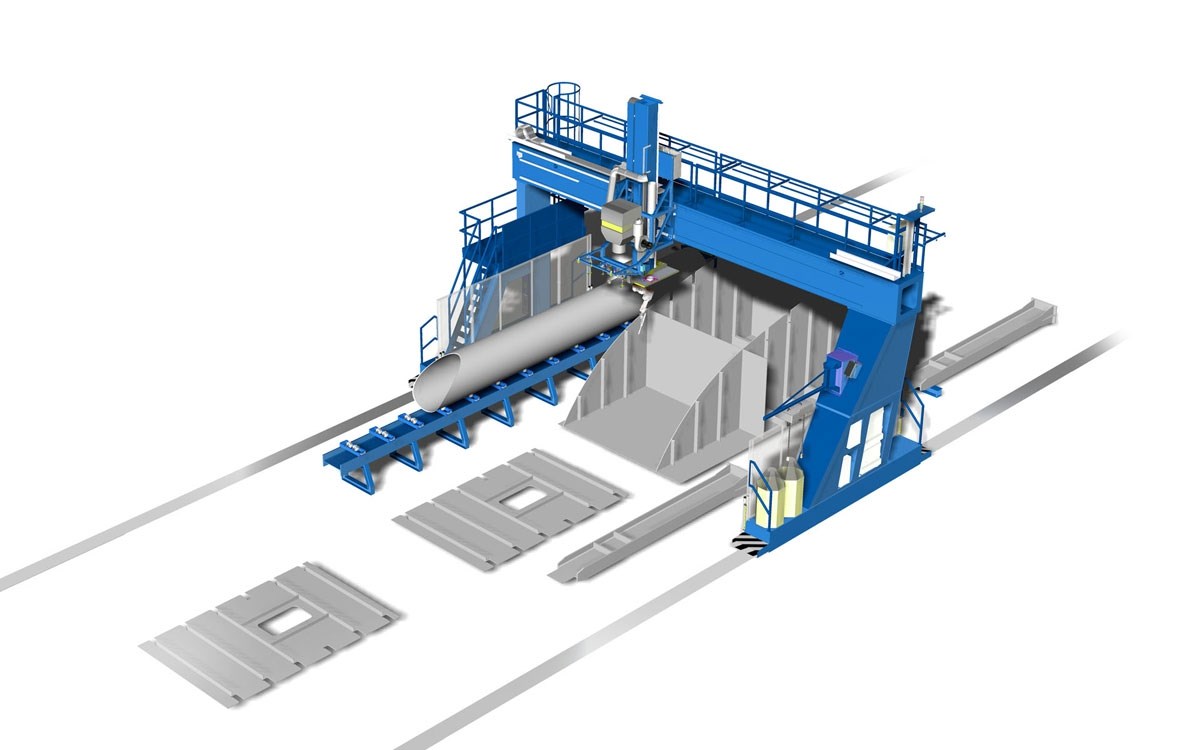

Besides steel profiles and beams, also round tubes are used as construction elements for structural steel industries. In practice, these profiles have large milling tolerances, resulting in large cutting deviations. KRANENDONK has developed special software to compensate profile tolerances giving exact dimensioned cuts. Since connections now fit much better, there is sustainable saving in welding hours.

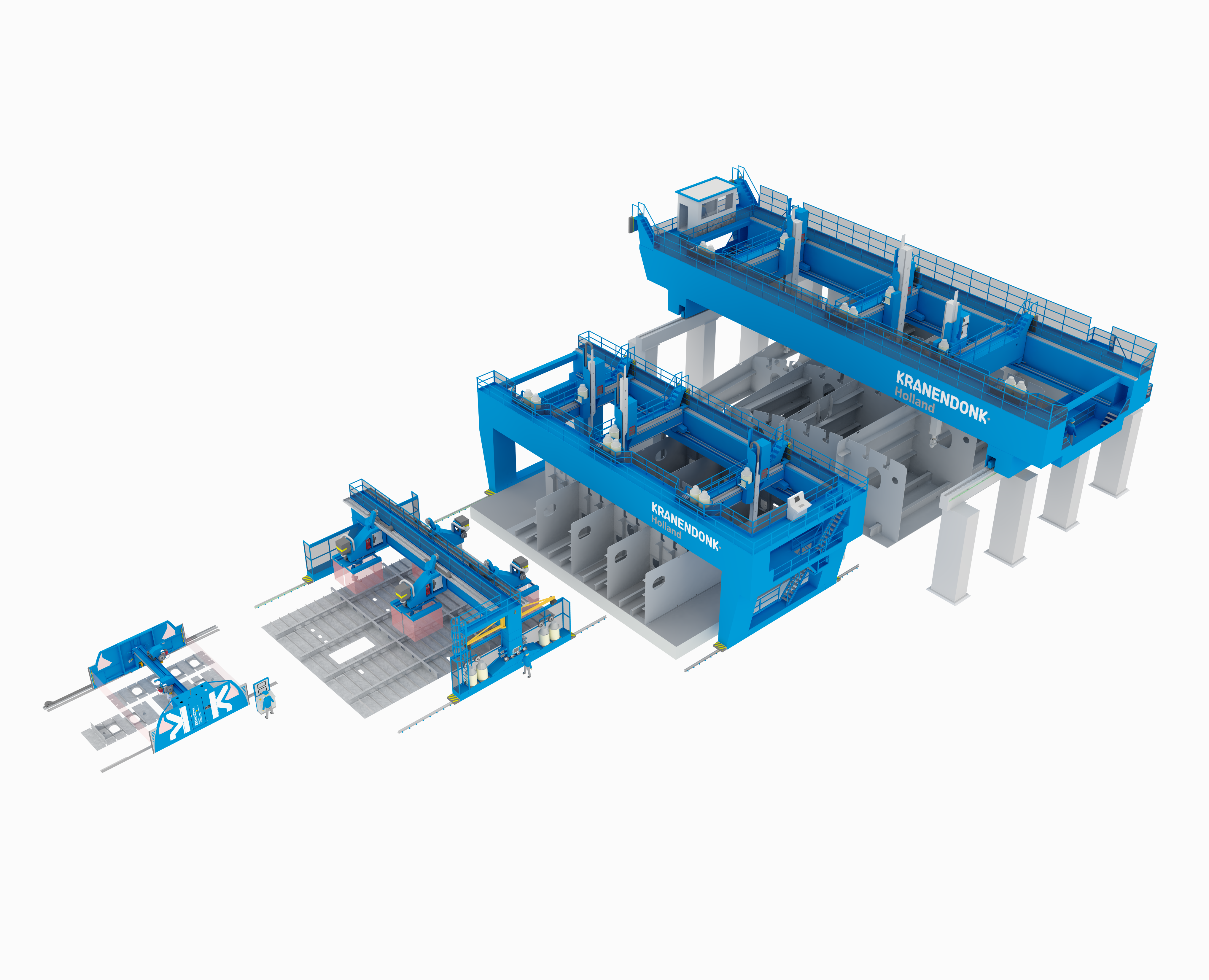

Especially for H-beam cutting, KRANENDONK developed Dynamic Flexibility Production (DFP) software in ARAC, which automatically adapts the robot program to the tolerances in H-beams. Not only does the beam have to fit, but because the structure will have to be welded, also a welding bevel must be provided. The system is ready to cut typical T, K and Y connections required for full penetration welding.

Automation when every product is unique? It's now available. Our advanced software will do all the robot programming for you, connecting design and production.

Capable to cut typical T, K and Y connections required for offshore constructions. Ensuring high quality fitting construction elements saving hours in welding time.

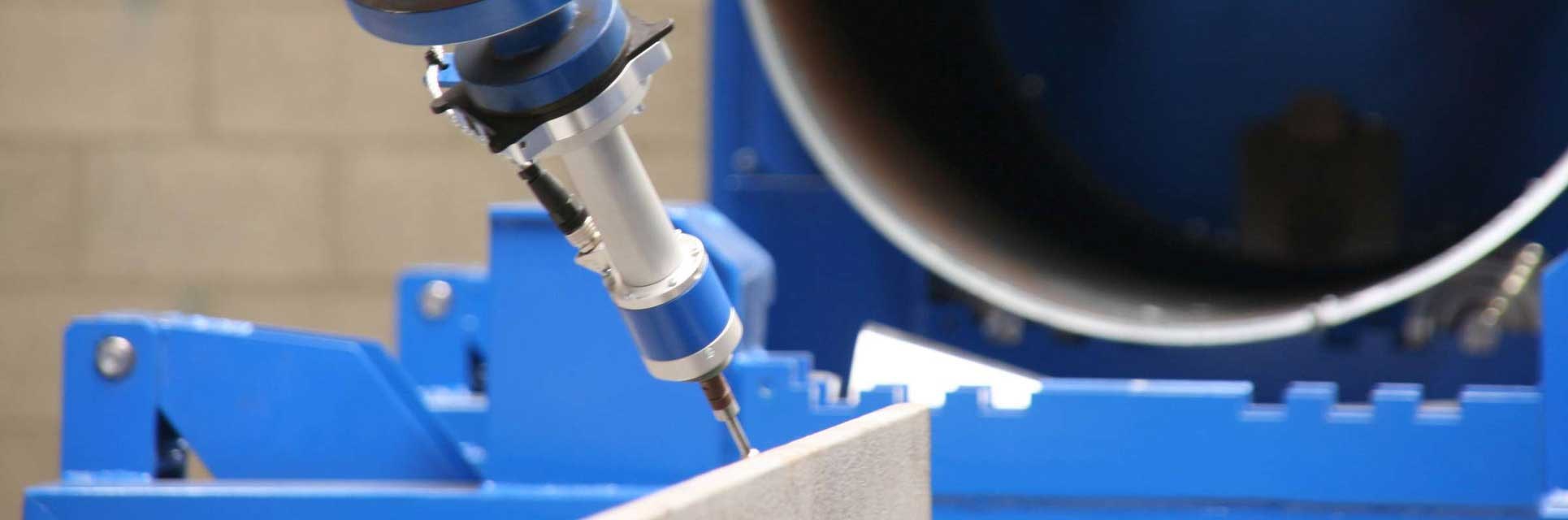

Before the actual cutting, all tubes and beams are measured at multiple points. The cutting path is adapted accordingly, to create better fitting parts for your products.

In order to join the tubes, special preparations must be cut on the branches to fit onto the main tubes. The correct angle of the welding bevel depends among others on the angle between the two tubes. This means also, that around the circumference of the tube, the welding bevel is constantly changing. This task can be fulfilled because the robot makes optimal use of its 8 axis’s.

Since sizes of products differ per customer different solutions for robot extension (tracks, columns and gantries) can be supplied. This means all axis of the robot carriers are controlled by the robot and therefore are able to work together as one coordinated system. If required the plate beveling functionality can also be supplied in multi functional systems.

One-piece production can be obtained by connecting the robot to the powerful offline programming software ARAC. The advanced ARAC software combines easy macro based programming of the robots with simple graphical online cell and process control. ARAC is able to interactively add the necessary processing information (CAM data) such as: which contours to process, processing speeds, process parameters, tool angles (e.g. torch angle) to create bevels. In case a CAD-interface is created, efficiency increases even more.