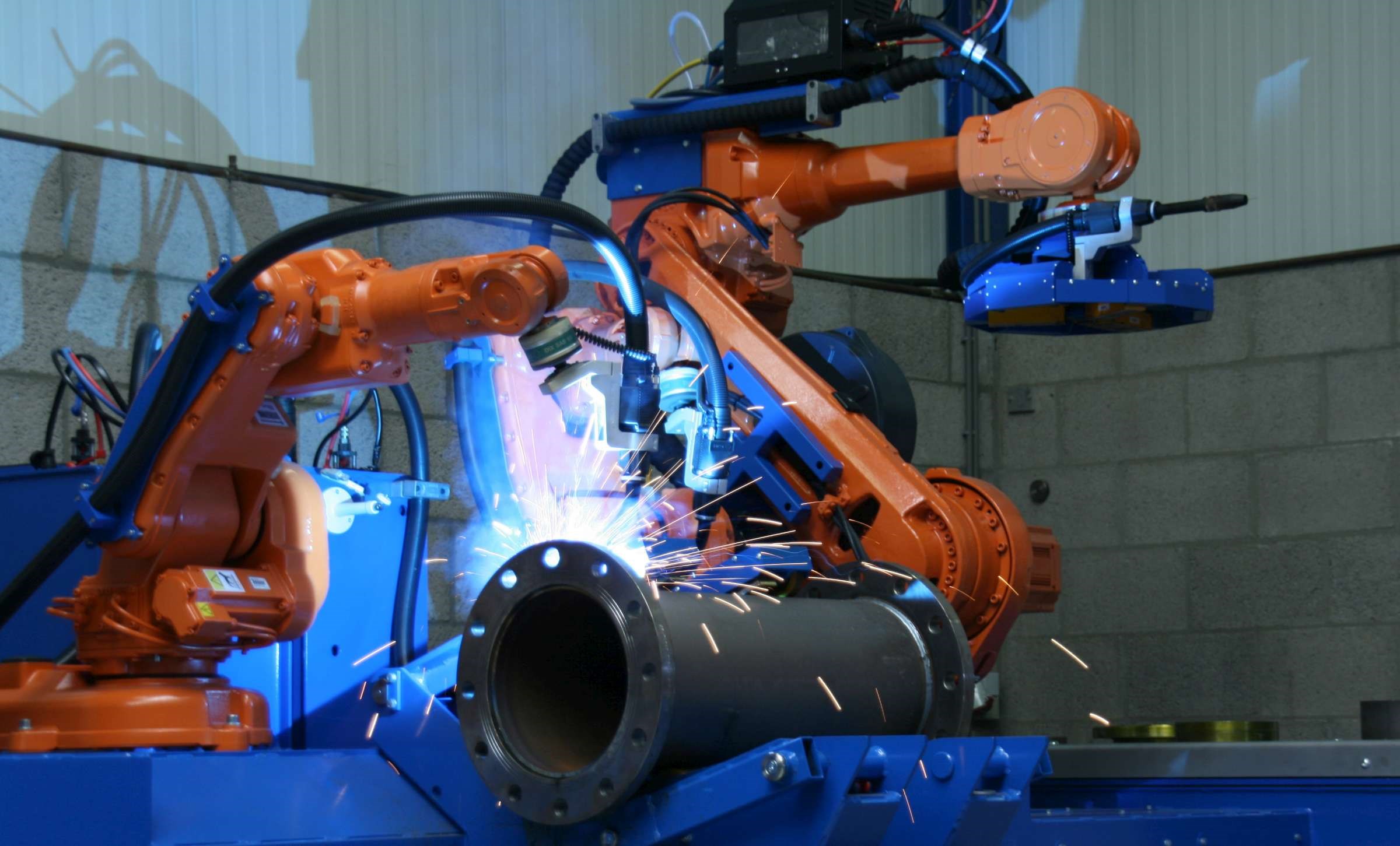

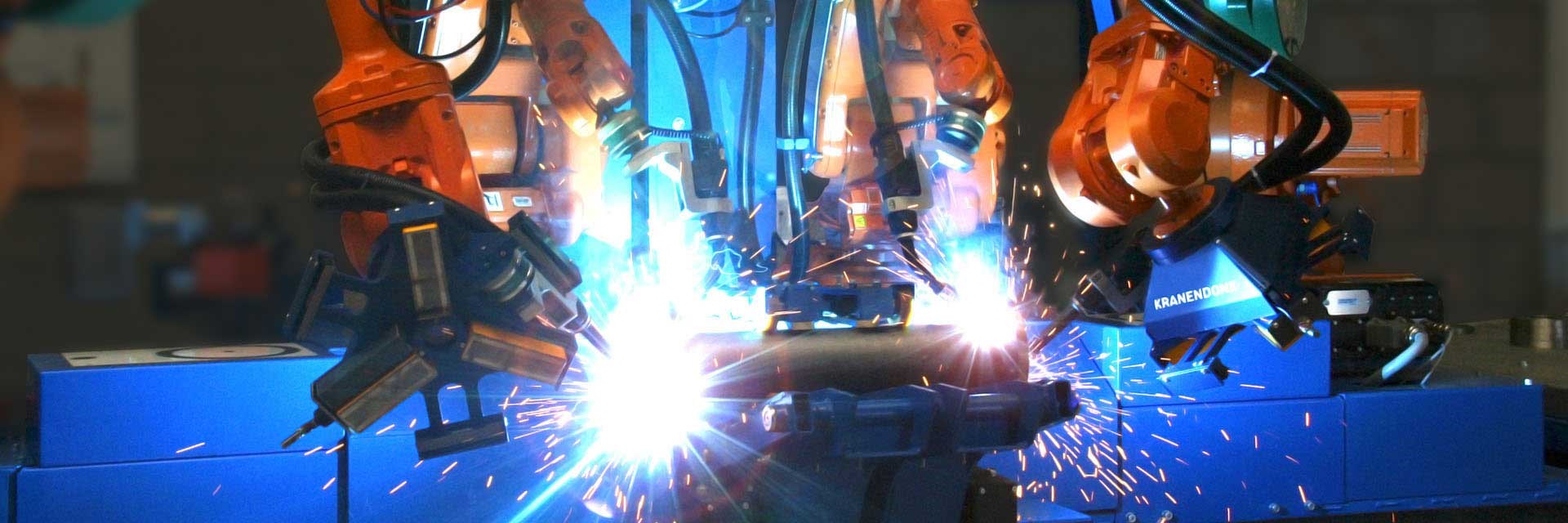

In cooperation with KRANENDONK from Tiel, the Netherlands, IHC Merwede has implemented a completely new and innovative flange welding system. KRANENDONK has a lot of know-how in the field of welding robots that cut and weld steel. The result: IHC Piping now boasts four new welding robots made by the reputable ABB.

For IHC Piping, a business unit of IHC Merwede, a flange to tube assembly system has been developed. IHC explains about this system:

'In cooperation with KRANENDONK from Tiel, the Netherlands, a completely new and innovative flange welding system was developed. Kranendonk has a lot of know-how in the field of welding robots that cut and weld steel. The result: IHC Piping now boasts four new welding robots made by the reputable ABB. The four robots are an integrated part of the fully automated piping production line. IHC Piping intends to continue to implement such innovations in their drive to build the piping factory of the future.'

'IHC Piping has been an independent IHC Merwede business unit since 2004. The young company is specialized in CNC controlled production and fabrication of piping systems. CNC is short for Computer Numerical Control, meaning the machines can translate the data of a digital design into a work order that makes the operation of the machine a whole lot easier.'

'IHC Piping’s main focus lies on the making of prefab pipelines. The tailor-made pipelines are transported to the new ship under construction where the whole system can be put together in record time. The pipes vary in diameter, from as small as 8 mm to over one metre in diameter. Shorter production time Traditionally, IHC Piping was a supplier to the dredging and offshore sector. But the company wants to expand into non-nautical sectors, such as the oil & gas industry and the offshore energy sector or hydraulics. In order to do so the company listens carefully to what the markets demand. And that is: lower prices. IHC Piping responds with lowering their Productions times through the deployment of high-tech production equipment.'

This machine received a nomination for the Maritime Innovation Award 2012.